Adjustable concrete battery casting mould

(10) WO 2022/180363 A1

(22) 14.02.2022

(43) 01.09.2022

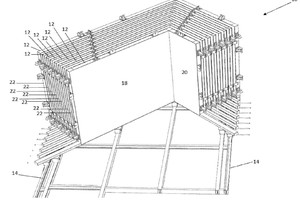

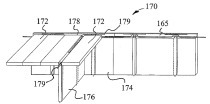

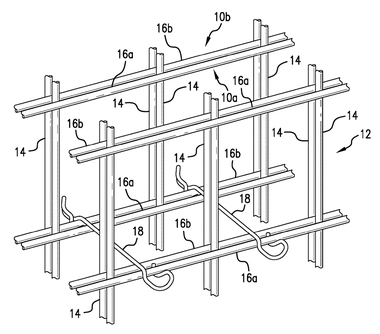

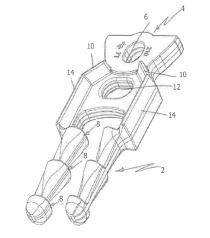

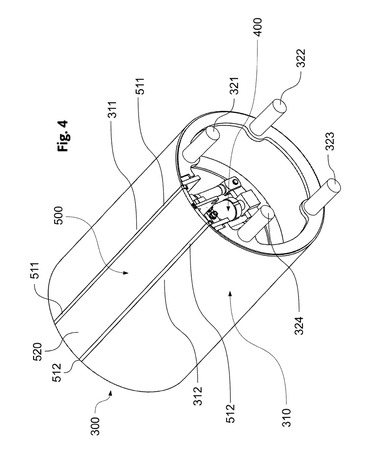

(57) The present invention provides a battery mould (10) for use in casting concrete, the battery mould comprising a plurality of leaf elements (12), each leaf element comprising an L-shaped body defining a first planar leg element (18) defining a first plane x, and a second leg element (20) defining a second plane y, the second leg element extending from the first leg element in a direction transverse to the first plane x, the first leg element defining a first end surface (22) distal to the second leg element and the second leg element defining a second end distal (24) to the first leg element, each of the first and second end surfaces having a capture locking bolt engagement portion; a plurality of capture bolt assemblies (26), each capture bolt assembly comprising a substantially planar capture base plate (28) defining a leaf element engagement portion for engagement with a respective capture locking bolt engagement portion, a locking bolt retaining plate (34) extending from the planar capture base plate, the locking bolt retaining plate defining an aperture (36) for receiving a locking bolt (38) therethrough, a locking bolt dimensioned to extend through the aperture, and a locking bolt engagement portion extending from the planar capture base plate, the locking bolt engagement portion configured to receive a portion of a locking bolt therethrough; and a plurality of discrete removable spacers (42), each stop member having a body defining a predetermined distance (d); and wherein, in use, the leaf elements are aligned with one another such that i) respective first leg elements are parallel to one another; ii) respective second leg elements are parallel to one another; iii) respective first end surfaces are aligned along a first commonplane; iv) respective second end surfaces are aligned along a second common plane; v) at least a portion of a spacer is located between adjacentleaf elements to space adjacent leaf elements distance (d) apart from one another: vi) the leaf element engagement portion of each capture bolt assembly is engaged with arespective locking bolt engagement portion so as to mount each capture bolt assembly on a respective leaf element such that the locking bolt extends in a directionparallel to the plane of the planar capture base plate; and vii) where there are adjacent leaf elements, a portion of the lockingbolt of one capturebolt assembly is securely received within the locking bolt engagement portion of an adjacent capture bolt assembly. The present invention further relates to a battery mould assembly comprising a plurality of the aforementioned battery moulds.

(71) Elcon Procedure Management Limited [GB/GB]; Newlyn House, Millfields Road, Ettingshall, Wolverhampton WV4 6JG (GB).