Combilift Unveils Self-Propelled Inloader at bauma 2025

07.04.2025

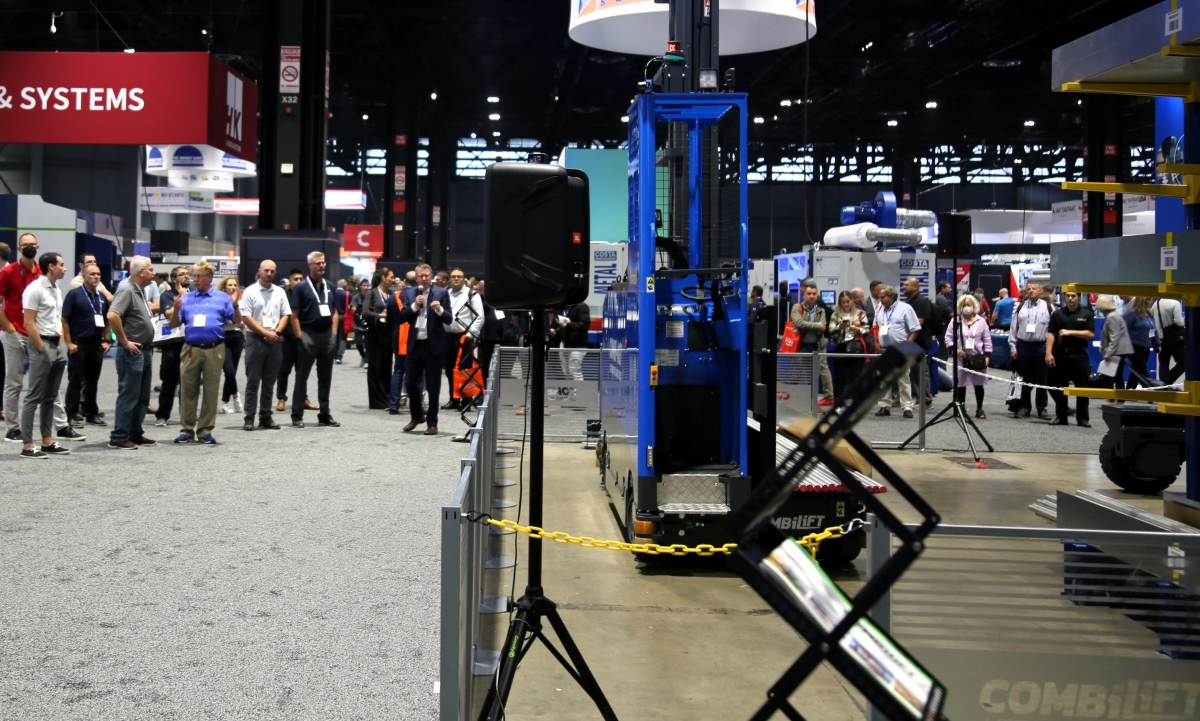

Figure: Combilift

Combilift, a global leader in innovative material handling, unveiled its pioneering Self-Propelled Inloader ‘COMBi-SPI’ at Bauma 2025. This highly anticipated launch marks a significant milestone in the transport of high loads, such as precast concrete, wall panels or glass A-frames, within production facilities and yard environments.

Revolutionising High-Load Transport

Development of the COMBi-SPI began in April 2022, driven by the need for an efficient, manoeuvrable, and cost-effective alternative to expensive trailers and trucks. The objective was clear: to create a versatile solution capable of handling 30-tonne loads on industry standard Inloader Pallets with superior visibility, agility, and ease of operation.

The collaboration with Spaansen, a specialist in precast concrete, influenced the design through to the final stages. Early prototypes focused on reducing overall length and width and enhancing manoeuvrability for working in busy production facilities. However, the project took a significant turn when Spaansen opted for a fully electric model mid-development. This shift required a complete redesign to integrate the electric wheel motors as well as fit the interchangeable batteries into the legs of the machine.

Advanced Features for Unmatched Performance

- Side-Facing Cab: Provides operators with a clear viewof both the load and direction of travel, ensuring enhanced safety and precision.

- Sliding Load Supports: Adjustable supports along the chassis to accommodate various load lengths and heights during travel.

- Pivoting Front Dual-Wheel Configuration: Eliminates the need for suspension, optimises stability and gives a tighter turning circle.

- 300mm Ground Clearance: Designed for both concrete and gravel yards, offering reliability across diverse work environments.

- Power Options: Available in Electric (with interchangeable battery system), Diesel, and LPG, catering to different operational needs.

- Large Solid Tires for durability and yard maintenance.

- Compact Yet Powerful: The short chassis enhances load support, maintains a low centre of gravity and offers more manoeuvrability, especially while operating within production facilities.

Industry-Changing Efficiency

With unmatched manoeuvrability and faster operational speed, the Self-Propelled Inloader transforms yard-based logistics by eliminating the reliance on multiple trailers and shunters, significantly enhancing efficiency and reducing operational costs for businesses handling oversized, high loads.

“This project showcases Combilift’s commitment to innovation and customer-driven design,” said Josh Moffett - Heavy Equipment Manager at Combilift. “We’ve leveraged decades of expertise in specialised transport machinery to develop a state-of-the-art solution that meets the evolving needs of the concrete and glass industries.”

The Self-Propelled Inloader is now on display at bauma 2025 at stand FS.1003/4. Attendees are invited to experience this revolutionary solution firsthand and discover how it redefines material handling for high-load applications.

CONTACT

Combilift Ltd

Annahagh,

Co. Monaghan

H18 VP65/Ireland

+353 47 80500