Agri-PV-frame: Sustainable utilization of prestressed carbon-reinforced concrete components through reuse

Since 2012, Ginkgo Projektentwicklung GmbH based in Dresden, Germany, has specialized in the pretensioning of carbon textile strands and uses its patented, state-of-the-art processes for producing precast elements with pretensioned carbon reinforcement. The pretensioning technology developed by Ginkgo is suitable for use in both short and long line casting beds. Ginkgo’s carbon-reinforced concrete roof system was the first to be granted a project-related approval as a primary load-bearing component.

The newly developed, sustainable prefabricated frame system made of prestressed carbon-reinforced concrete was developed jointly by Ginkgo Projektentwicklung GmbH, Dresden, and Fink Ingenieure GmbH, Radebeul. This system is designed to provide a cost-effective, sustainable roofing and support structure for ground-mounted photovoltaic systems. Protecting steel frames or conventional steel-reinforced concrete against corrosion usually poses a challenge in terms of durability owing to weather impact. In contrast, carbon-reinforced concrete shows excellent resistance to these conditions. In hot climates, shading combined with controlled irrigation through the frames favors agricultural use of the land.

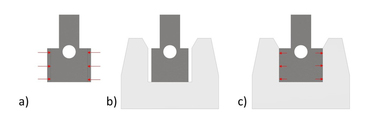

One of the major benefits of this frame system lies in the assembly characteristics of its individual parts and the fact that connections can be loosened several times. The modular, detachable system is particularly suitable as a support structure for photovoltaic systems because it allows the structures to be moved to other sites after the end of their intended use, resulting in a total service life of more than 100 years.

The components’ load-bearing capacity was verified using established methods and full-scale tests. The application process for the project-related approval is currently in the final stages.