Conwood frameworks – revolutionary composite system made of timber and carbon concrete

The Conwood frameworks product series can rightly be called a true world first. Because the innovative hybrid module made of timber and carbon concrete opens up entirely new possibilities in housing construction, the first carbon concrete-timber composite module originally developed by beton design factory based in Schönborn was awarded the Bundespreis (Federal Award) 2016 at the Handwerksmesse (Trade Fair for Craft Trades) and is currently among the TOP 10 nominees for the much-coveted GreenTec Award. In collaboration with V. FRAASSolutions in Textile GmbH based in Helmbrechts – manufacturer of the element-optimized “SITgrid” carbon reinforcement – and Laumer Bautechnik GmbH based in Massing, development of the revolutionary hybrid module is currently being advanced under the name of Conwood frameworks.

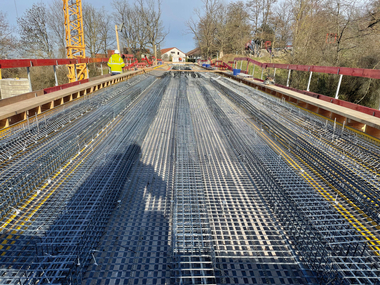

The Conwood frameworks product series is a new type of building system in which both timber frame construction and the precast concrete façade are allowed to play out their strong points. The ground-breaking innovation: a 20-mm thick, or thin, carbon-reinforced fine concrete slab is combined with a timber frame element. A durable hybrid element is thus created which meets all the requirements of modern housing construction.

New creative possibilities

As recently as November 2016, the carbon concrete technology used in this project was awarded the German Future Prize (Deutscher Zukunftspreis), the Federal President’s Award for Technology and Innovation, which is one of the most important science awards in Germany. Supplying the carbon grid fabric used as reinforcement, V. Fraas Solutions in Textile GmbH has been a key player in the production of this ultra-light and innovative type of concrete. With its two managing directors, Roy Thyroff and Alexander Schmidt, the company is a driving force in the currently largest German research project in construction engineering, the C³ project.

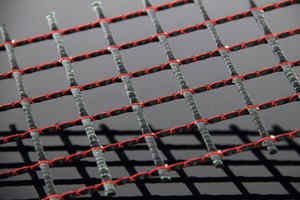

The excellent ratio between element stability and weight is one of the outstanding features of the Conwood frameworks hybrid module. It is made possible by the use of a two-dimensional carbon fabric (SITgrid) from V. FRAAS Solutions in Textile GmbH in combination with an ultra-high-performance concrete. The high-strength carbon grid features a ribbed surface texture to ensure an optimum bond with the surrounding concrete. This is achieved by wrapping the high-performance fiber with a filament of smaller diameter. In contrast to the 48 k or 50 k yarns usually available on the market, the specially developed high-performance textile is spun from a 96 k or 100 k yarn, respectively.

The prefabricated elements produced from this material provide numerous sustainable benefits for housing construction: in indoor application, the exceptionally slender hybrid walls offer entirely new creative possibilities. As exterior walls or façades, they impress with thermal and sound insulation, durability, reduced costs of transport and assembly, as well as shorter construction periods.