Alterations of the future DIN 1045 series for precast concrete products

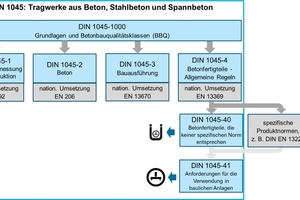

In August 2023, the new generation of the DIN 1045 series of standards was published. It comprises seven parts in total, encompassing structural concrete construction from planning to concrete and the execution on the construction site through to the production of precast concrete products.

Of the seven new parts of the standard, cf. Figure 1, six have been quoted in the -current Model Administrative Provisions – Technical Building Rules 2024/1 (MMV TB) and successively be implemented in the Federal States in building law. Apart from numerous technical amendments and adaptations as against the last standard generation, being more than 15 years old, in particular, DIN 1045-1000 [7] „Basic Principles and Quality Classes of Concrete Construction (BBQ) and DIN 1045-41 [6] „Requirements for the use of precast concrete elements in structures“ are new.

BBQ classes – almost irrelevant to precast concrete products

The completely new DIN 1045-1000 [7] provides a new class concept including planning, concrete and execution classes as well as a quality class of concrete construction (BBQ class), deriving therefrom. In terms of communication, planning, execution of building structures, and concrete, these classes specify three requirement levels each:

normal (N)

elevated (E)

special (S)

Depending on these requirements, structural components made of cast-in-situ concrete according to DIN 1045-1000 [7], Table no. 2, are assigned to a planning class (PK-N/E/S), a concrete class (BK-N/E/S), an execution class (AK-N/E/S) and the quality class of concrete construction (BBQ-N/E/S), deriving therefrom. The latter is the basis for communication concepts, partly including BBQ tender and execution discussions as well as a concreting concept, (further) developed in such discussions.

In the production of precast concrete products and the construction with precast concrete elements, there are other interfaces than in cast-in-situ concrete construction, which may vary considerably depending on the contractual constellation. Therefore, DIN 1045-1000 [7] describes in Annex A.3 a communication concept specifically for precast concrete products, regardless of the BBQ classes. In principle, a classification in a BBQ class, therefore, is not provided for precast concrete products, cf. DIN 1045-1 [1], Section 4 (2). Likewise, BBQ tender and execution discussions are not provided for precast concrete products. The concreting concept is in the sole responsibility of the manufacturer of precast concrete products. As the requirements related to communication and its documentation according to DIN 1045-1000 [7] is not apply as Technical Building Rules, there is no obligation to categorize precast concrete products in BBQ classes under building law.

The execution class according to DIN 1045-3 [3] is exclusively referred to for the execution of cast-in-situ concrete works. The production of precast concrete products is completely governed under DIN 1045-4 [4] and the supplementary product standards and does not refer to the execution classes stipulated in DIN 1045-1000 [7]. Hence, a classification into execution classes shall not be made for precast concrete products.

However, the situation is different in case of concrete classes. Since precast concrete products are frequently made of concretes that suppose elevated or special requirements in terms of DIN 1045-1000 [7], Table no. 2, a concrete class must be stated for precast concrete products too, at least if it deviates from BK-N. This „activates“ the corresponding provisions stipulated in DIN 1045-2 [2].

For planning, DIN 1045-1 [1], Section 4 (6) provides that a planning class PK-E or PK-S must be chosen for planning tasks requiring extended or special coordination of the planner with the concrete producer or the contractor. The manufacturer of precast concrete products performs the tasks of the concrete producer towards the planner. If, however, planning leads to an elevated or special need for coordination with the precast producer in terms of the concrete to be used, classification into a planning class should be made. This may be the case, for example, for special requirements arising from the utilization, which are not completely covered by the exposure classes, for specifications regarding the roughness of surfaces, for use in sewage, slurry and silage (SSS) facilities or LAU facilities or for individual fair-faced concrete properties.

The new DIN 1045-4 and DIN 1045-40

In the field of precast concrete products, the numbering of the standard parts was adapted to the rest of the DIN 1045 series. The national application rules regarding the European Concrete Standard DIN EN 205-1:2001 [16] and regarding the European Standard DIN EN 13670 [21] for the execution of concrete structures had already been included in the standard parts DIN 1045-2:2008 [8] and DIN 1045-3:2012 [9] previously. The national application rules regarding the previous European precast concrete standard DIN EN 13369:2004 [20) on the contrary were published as DIN V 20000-120 [22]. The old DIN 1045-4:2012 [10] was instead a national (residual) product standard for not yet Europe-wide standardized structural precast concrete elements. In the future, the systematics of publishing national application rules in the standard parts of DIN 1045 will be adopted for precast concrete products too. At the same time, the decision was made to release consolidated standards, meaning that the European standard and the national application rules will be published in an interlinked document to improve readability. The new DIN 1045-4 [4] will therefore contain the complete national implementation of the current DIN EN 13369 [19] including all related national provisions. Hence, DIN V 20000-120 [22] is omitted. Precast concrete products, so far falling within the scope of the old DIN 1045-4:2012 [10], will be covered in the new part DIN 1045-40 [5] in the future.

Other than for concrete (DIN 1045-2 [2]) and the execution of structures (DIN 1045-3 [3]), the general requirements on precast concrete products will always be supplemented by an additional product standard, according to the new DIN 1045-4 [4], see Figure 1. This product standard still includes individual product-specific regulations. Numerous European product standards supplementing the old DIN EN 13369:2004 [20] (and DIN V 20000-120 [22]) were already applied in the past. In many sections, the old national product standard DIN 1045-4:2012 [10] also referred to DIN EN 13369:2004 [20] and supplemented the same. In detail, however, a number of different provisions existed between the precast concrete products standardized on a European level and those according to the old national DIN 1045-4:2012 [10]. These discrepancies were eliminated in the new standard generation. In the future, the new general rules regarding precast concrete products according to national DIN 1045-4 [4] will apply similarly for products according to the European product standard and according to the national standard DIN 1045-40 [5]. Only the rules concerning the conformity assessment will continue to be governed by the Construction Products Regulation on a European level and nationally they will be governed by the regional Building Codes as well as the Administrative Provisions on Technical Building Rules of the individual Federal States. In respect of all technical aspects, DIN 1045-40 [5] therefore exclusively contains references to DIN 1045-4 [4]. Only Section 6 on assessment and verification of constancy of performance refers to requirements under building law and System A embodied therein in accordance with DIN 18200 [12], which is the basis for a certificate of conformity.

DIN 1045-41: Producible - tradable - usable

Until 2016, it was obligatory to label each structural precast concrete element with an Ü mark and in case of European harmonized precast concrete products with a CE marking additionally. In this way, it was documented that in the production of the concrete component not only the properties stated in the Declaration of Performance in accordance with European codes, but also additional national requirements under building law were taken into account. This includes, for example, the national requirements on concrete (e.g., evidence of alkali) and on reinforcement steel or prestressing steel wire (DIN 488 [11] or national technical approvals).

For legal reasons, double labeling with CE and Ü marking was no longer allowed as of 2016. As a consequence, the users of concrete components could no longer prove that the requirements concerning the production of precast concrete products were met as stipulated in national building law. As of 2016, associations of the precast concrete industry therefore published so-called requirements documents in the alternative, providing a comprehensive overview of the additional national requirements on precast concrete products. On the basis of these requirements documents, the manufacturers could declare the compliance with these additional national requirements for building structures in a legally binding way by means of the Manufacturer‘s Declaration or could have their products monitored and certified under private law by a third-party inspection body.

Now, these requirements documents issued by associations are replaced with DIN 1045-41 [6] by a standard. As a result, it is no longer just a recommendation of associations, but a recognized state of the art. A national implement DIN 1045-41 [6] will not take place, as this again would lead to additional requirements on the product level on the part of building authorities, which are not permitted. In the future, the manufacturer will be able to prove the applicability towards his customer by a binding Manufacturer‘s Declaration based on DIN 1045-41 [6]. Such proof is a normative requirement stated in DIN 1045-3 [3], Section 5.1 (2) e) for the use of precast concrete products. The extent of the Manufacturer‘s Declaration results from DIN 1045-41 [6], Table nr. 2. Further general information regarding the layout of the Manufacturer‘s Declaration can also be found in DIN 18200 [12], Annex A. According to MVV TB, Section D.3, the correctness of the Manufacturer‘s Declaration concerning the compliance with DIN 1045-41 [6] should be documented involving a recognized body. In other words, a certification of the compliance with DIN 1045-41 [6] under private law will become common practice.

To put it in more simple terms: DIN 1045-4 [4] includes the essential technical information for the production of precast concrete products, the European or national product standards, such as DIN EN 13225 [18] or DIN 1045-40 [5], govern the formal requirements so that the precast concrete products can be traded and DIN 1045-41 [6) includes the specific requirements so that precast concrete products can be used in building structures in Germany.

The compliance with all three standards will become subject of third-party inspection, with the legal basis for third-party inspection and thus the type of certification differing as follows:

DIN 1045-4 [4] and national product standard DIN 1045-40 [5] -> Certificate of Conformity in accordance with the regional Building Codes of the Federal States

DIN 1045-4 [4] and the harmonized European product standard -> Internal Production Control Certificate (WPK) in accordance with Construction Products Regulation

DIN 1045-41 [6] -> Certification under private law

What else is new?

Even the new standard generation will not change concrete construction fundamentally. But the more than 360 pages of the entire new DIN 1045 standard series include a large number of alterations which, however, cannot be addressed and explained within this article to its full extent. On introduction, the relevant standard parts shall be read intensively. In this regard, it shall be checked whether the specific activities are affected by any changes. A small number of significant alterations concerning precast concrete products is mentioned below, without being fully and conclusively.

High-strength concrete

For normal concrete with a higher strength from C55/67 onwards, partially deviating requirements on the Internal Production Control (WPK) and the composition were effective until now. This limit will be raised in the new standard to C70/85. For normal concrete from C70/85 to C100/115 and lightweight concrete from LC55/60 to LC80/88, a number of additional provisions must be considered, among other things, an extended WPK, specifications on the alkali classification of aggregates or concerning the maximum cement content. The monitoring class 3 will be omitted in the future. Starting from strength class C90/105 and LC70/77, moreover, additional evidence of national technical approvals (abZ/aBG) will still be required.

Self-compacting concrete

The regulations concerning self-compacting concrete under the old DIN EN 206-9:2010 [17] and the DAfStb Code of Practice on self-compacting concrete [25] have been taken over in the new DIN 1045-2 [2] to a great extent.

Minimum paste content and extended initial testing

For assuring the workability of fresh concrete on the construction site, new minimum values for the paste volume were stipulated in DIN 1045-2 [2], Table nr. 16. If these values are lower, extended initial testing is required according to Section 9.5. As this additional tests are primarily addressed to the interface between concrete producer and concrete processor in the context of the construction site, the extended initial testing can normally be omitted at the precast concrete plant manufacturing its own concrete, except for the determination of a minimum mixing time. In respect of the determination of the minimum paste content, it has to be considered that this does not correspond to the paste volume according to DAfStb Code of Practice on concrete construction when handling substances hazardous to water [23].

New cement types

New cement types, e.g., CEM II/C and CEM VI cements are newly incorporated in the new DIN 1045-2 [2], cf. DIN 1045-2 [2], Annex F. Moreover, normatively governed applications were partially extended substantially, in particular, for the CEM II-M cements. For certain fields of application, so far, these cements could not be used at all or only on the basis of evidence of national technical approval (abZ/aBG/ZiE).

Reclaimed aggregates

The previous concrete standards DIN EN 206-1:2001 [16] and DIN 1045-2:008 [8] only provided the use of reclaimed aggregates, being washed out of residual water or fresh concrete. According to the new DIN 1045-2 [2] also aggregates reclaimed by crushing of fresh concrete may be used. In this regard, the fresh concrete must not have been used in construction before and the reclaimed aggregates must only be used by the manufacturer internally or a group of manufacturers. This restriction is to ensure that the aggregates reclaimed by crushing are known including their starting materials and that no negative changes, e.g., by contaminations, input of substances or something similar, have occurred.

In case of reclaimed aggregates not being separately processed, that are added as a specific group of aggregates, the maximum grain size must be considered. Other restrictions for the use of reclaimed aggregates are dependent on the type of reclaiming, the intended volume share of the total volume of aggregates (GK) used, the processing and the extent of quality assurance, cf. Table 1.

Regardless of the usability of hardened residual concretes for reclaimed aggregates in accordance with DIN 1045-2 [2], constellations are conceivable where the hardened concrete might come under the waste law before being crushed, making the reuse possibly more complicated from a legal point of view.

Recycled aggregates

The possibilities of using recycled aggregates were somewhat extended as against the old DIN 1045-2:2008 [8] and the DAfStb Code of Practice on concrete with recycled aggregates [24]. In concrete class BK-N recycled aggregates can be used up to a volume proportion of 25 % as exchange of coarse aggregates (relative to the total aggregates), if the general requirements on recycled aggregates according to DIN 1045-2 [2], E.3.1, are adhered. Under certain conditions, a higher proportion of recycled aggregates is also permitted in concrete class BK-E. Even the use of recycled fine aggregates is permitted according to the new DIN 1045-2 [2] within narrow limits, cf. Table 2.

Conformity control and conformity criteria for concrete

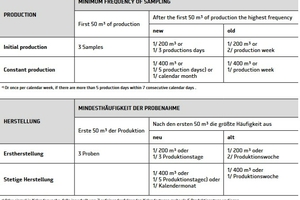

The minimum frequency of sampling for normal concrete up to C60/75 was slightly altered, cf. Table 3. However, in many cases this will not require any adjustments to the usual sampling routine.

Treatment at the precast factory

The regulations concerning curing times according to the old DIN 1045-3:2012 [9], that were referred to so far, were replaced in the new DIN 1045-4 [4] by the European regulations laid down in DIN EN 13369 [19] and are clearly shown in a separate table in DIN 1045-4 [4], Annex P, Table P.1. Unfortunately, exposure class XS was forgotten at the time of printing DIN 1045-4 [4]. However, the corresponding information can be taken from DIN 1045-4 [4], Section 4.2.1.3 and are supplemented in Table 4. The new regulation reduces the requirements concerning the minimum compressive strength at the end of curing for exposure classes XC2 - XC4, XD1-XD2 and XF 1 as well as for concretes exhibiting substantially higher strengths than the minimum strength required for the respective exposure class (this does not apply to XM). But it should also be noted that the manufacturer of precast concrete products is measured, in the first place, in terms of success of the treatment and not in terms of its duration. Before changing the curing process, it should in so far be critically checked whether the new option for reducing the minimum duration of curing will reliably result in a flawless precast concrete product, even under unfavorable conditions.

If no proof regarding a strength test must be submitted, the values required concerning the duration of curing laid down in DIN 1045-3 [3], Section 9.6, Table no. 6 and 7, in particular, can be regarded as equivalent proof.

Heat curing

In respect of the requirements on heat curing, initially, the European regulations were also adopted as laid down in DIN EN 13369 [19], see DIN 1045-4 [4], Section 4.2.1.4. They allow slightly higher temperatures to some extent, both during the pre-storage and during the heat curing process. In case of wet and cyclic wet and dry environmental conditions and in the absence of long-term experience simultaneously, an additional verification of the suitability of the heat curing process is required. However, the DAfStb Code of Practice on heat curing of concrete [26] can still be applied, if long-term experiences have been gained accordingly.

Manufacturing tolerances

Since the withdrawal of DIN 18203-1, Tolerances in Building Construction – Part 1: Prefabricated products made of concrete, reinforced concrete and prestressed concrete [14], there has already been the problem that there is no normative regulation coordinated to national tolerances of building structures in accordance with the standard on tolerances DIN 18202 [13] that applies to the manufacturing tolerances of precast concrete products. This gap was filled in the new DIN 1045-4 [4] by an informative Annex Q. This again contains tolerances for precast concrete products, being coordinated to the national requirements of building structures. For formal reasons, it was unfortunately not possible, to make this Annex Q normative and thus binding. Strictly speaking, Annex Q now must be agreed upon within the request for proposals and the contract award separately. Provided that DIN 18202 comes applicable for a building structure, it shall be assumed that the tolerances according to Annex Q shall apply for the definition of the usual quality of a precast concrete product in Germany. Therefore, the compliance with Annex Q of DIN 1045-4 [4] is highly recommended.

Testing plans for internal production control (WPK)

The WPK testing plans in accordance with DIN 1045-4 [4], Annex D, in comparison to old regulations (DIN EN 13369:2004 [20] and DIN 14045-4:2012 [10]) was harmonized and thus adapted slightly. When adapting the production process and the internal production control to the new standard generation, it is urgently recommended to check the testing plans stated in the WPK manual whether they still fully comply with the regulations of the new DIN 1045-4 [4]. If necessary, minor adaptations may be required here.

Use of ready-mixed concrete in the precast concrete plant

In some precast concrete plants, ready-mixed concrete supplied by another manufacturer is used for the production of precast concrete elements. This has to be in any case a certified ready-mixed concrete, for which the concrete manufacturer has already provided a declaration of conformity. Nevertheless, the precast concrete plant has to make ensure, that the concrete exhibits the required characteristics on delivery, similar to the acceptance tests of ready-mixed concrete at the construction site. In contrast to construction sites, precast concrete plants and their suppliers of ready-mixed concrete normally have long-term experiences concerning both the used types and the delivery routes, etc. Gross errors, such as the delivery of a wrong concrete, should therefore be unlikely and should be identified as part of the control of the delivery note and visual controls of the well-known concrete, as set out in the internal production control. Nevertheless, tests shall be carried out on a regular basis, whether the concrete arriving at the precast concrete plant still exhibits the characteristics, it shall feature according to the list of varieties and the conformity assessment of the manufacturer. Until now, the performance of such tests was mandatory according to standards for precast concrete products, however, the extent of testing and assessment criteria were not always consistent. The new DIN 1045-4 [4], Section 6.3.6.3 now stipulates a clear regulation concerning the minimum extent of sampling and the assessment criteria of such testing. In this regard, reference is made to identity testing of the compressive strength in accordance with DIN 1045-2 [2], Annex B. A minimum of 2 samples shall be taken per 400 m³ or per production week (higher frequency decisive). The identity criteria shown in table 5 as set out in DIN 1045-2 [2], Table B.1, shall apply for the assessment.

Summary

The systematics of quality classes of concrete construction introduced for ready-mixed concrete within the new DIN 1045 standard series will only come into effect for precast concrete products to a limited extent. In case of precast concrete products, only the concrete class shall be specified, if deviating from BK-N, and a planning class in accordance with DIN 1045-1000 [7] optionally. Execution classes and summarizing BBQ classes as well as the communication concepts obligatory for cast-in-situ concrete construction along with BBQ tender and execution discussions do not exist for precast concrete products.

In future, for structural precast concrete elements another certificate in accordance with DIN 1045-41 [6] under private law will become common practice, apart from the certificate of conformity (Ü mark) or the WPK certificate (CE labeling). This will replace certificates on the basis of requirements documents issued by associations that are already usual at many companies and will furnish evidence of usability in German building structures.

Apart from structural amendments in the new DIN 1045 standard series, there will also be numerous technical amendments of more or less importance. These effect both details to the concrete composition and regulations concerning the internal production control as well as the conformity assessment. In particular, it was cautiously attempted to comply with the changing ecological requirements by extending the possible applications of reclaimed and recycled aggregates and (new) low-clinker cements. With the adoption of the European standard specifications, e.g., for post-treatment or heat curing of precast concrete products, the European regulations were implemented, while the known German procedures, which are on the safe side, can still be applied too.

CONTACT

Verband Beton- und Fertigteilindustrie Nord e.V.

Dr.-Ing. Jens Uwe Pott

Raiffeisenstr. 8

30938 Großburgwedel/Germany

![Restrictions and/or preconditions for the use of reclaimed aggregates in accordance with DIN 1045-2 [2], 5.2.3.3](https://www.bft-international.com/imgs/2/1/4/8/3/6/6/tok_72587f1d01ff046276bf3a43ed7d6b3a/w300_h200_x334_y394_Tabelle_1-a5cb407b1383fdeb.jpeg)

![Possible applications and/or preconditions for the use of recycled aggregates according to DIN 1045-2 [2], 5.2.3.4](https://www.bft-international.com/imgs/2/1/4/8/3/6/6/tok_c3c36808d7ab0a5922f18c242031ba29/w300_h200_x334_y403_Tabelle_2-a1e5ff744a8a3c88.jpeg)

![Minimum strength of concrete at the end of curing in accordance with DIN 1045-4 [4] rectified](https://www.bft-international.com/imgs/2/1/4/8/3/6/6/tok_b7db1fd4bc6fcdc5fb409014daead145/w300_h200_x334_y230_Tabelle_4-7f5e66714d9e2079.jpeg)

![Identity criteria for the compressive strength, source: DIN 1045-2 [2], B.3](https://www.bft-international.com/imgs/2/1/4/8/3/6/6/tok_7c20e00e4b66e4fb570a46f3a8867714/w300_h200_x334_y119_Tabelle_5-1cf549033a1616c4.jpeg)