BIM in the precast industry

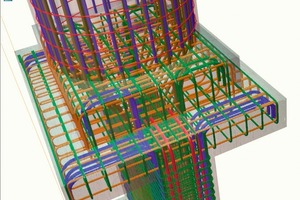

The concept of BIM (Building Information Modeling) describes an integrated, end-to-end process for the design, building and use of structures. As an extension to conventional CAD systems, BIM creates the basis to convey consistent information to all parties involved in a timely fashion. There is hardly any other CAD application where BIM plays a more significant role than in precast element design. The design, production, delivery and assembly of elements are often taken over by one and the same contractor so that an integrated solution results in a tangible immediate benefit.

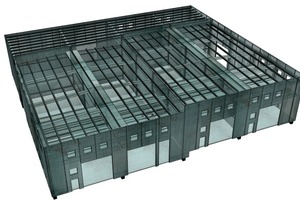

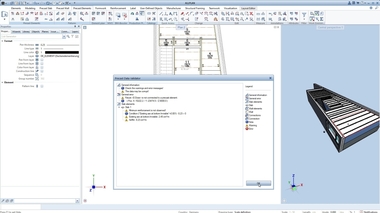

Plants with circulation lines and robots

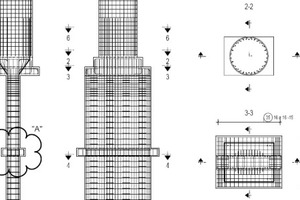

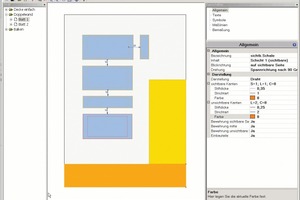

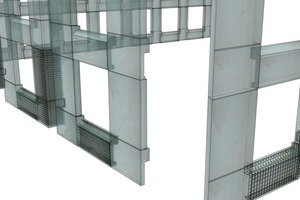

First of all, BIM means 3D design. In addition, non-geometrical information can be described, such as the surface quality of a precast unit. This makes it possible to perform any subsequent work step directly without having to enter data again. The advantage is obvious: no new data input, no error sources, immediate calculation.

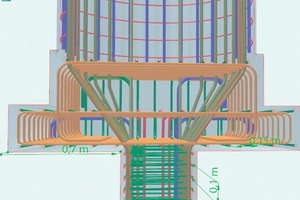

Given all the benefits, these 3D applications have already gained a major share in designing and producing flat elements such as floor slabs and walls, which are manufactured with a high degree of automation. As the output of the...