Higher efficiency through multi-functional shuttering robots

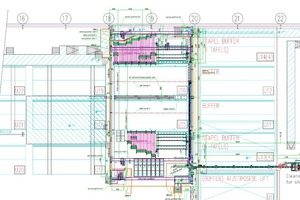

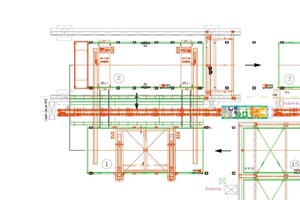

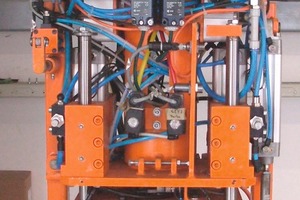

The first shuttering robots that were put into operation nearly 20 years ago represented the logical further development of previous automation steps. Automation in the area of shuttering had begun with the “plotter,” a machine using a color nozzle to trace onto the pallet the contours of the products to be manufactured. Soon after, a device followed that not only traced, but also carried out several tasks consecutively: transverse formwork removal from the pallet, pallet storage management, pallet cleaning, plotting, re-positioning of the transverse formwork on the pallets, and (not least) oiling of the formwork.

The designations used for this first “multifunction shuttering machine” are many – MRP, RES, QRP, etc. The following article will therefore use the term “shuttering machine” throughout.

The disadvantage of this equipment becomes particularly apparent in wall production plants: of the frequently highly complex contours of the walls, only the first and last edge can be shuttered; everything between must be carried out later manually. The problem, however, is inherent to the system and cannot be solved on this particular machine. The design of this machine makes impossible the placement of...