New ways of efficient reinforcement for columns

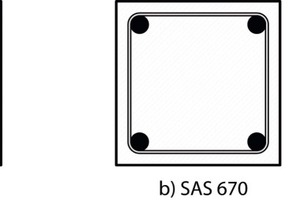

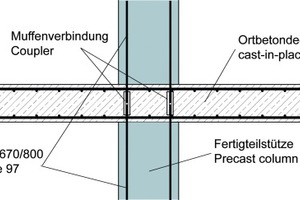

Higher, slender, safer – this have been slogans even before the opening of Burj Khalifa in Dubai, the worlds highest building with a height of 828 m. The construction shall follow the demand of maximum height and extraordinary architecture. Costs shall be as low and durability as high as possible. High and ultra high performance concretes have already been developed [1]. Now steel producers are going to follow. For more than 10 years high strength reinforcement SAS 670/800 (grade 97) developed by Annahüttehas been used successfully for geotechnical applications like anchors, soil- and rock nails and piles. This steel will now be used as concrete reinforcing too.

Standards regulations and divergences

Current structural codes permit yield strength of reinforcement bars up to fy = 500 N/mm² (DIN 1045-1) respectively fy ≤ 600 N/mm² (EN 1992-1-1). Reinforcement ratio is limited with r ≤ 9% (DIN 1045-1) respectively r ≤ 8% (EN 1992-1-1). Further constraints are given for maximum diameter for main bars and minimum diameter and maximum span for stirrups.

For the design of high strength columns (HPCM – High performance compression members, predominantly stressed) all those constraints will be surpassed:

» Yield strength fy = 670 N/mm²

» Reinforcement ratio r ≤ 20%

...

![Fig. 1 Load redistribution due to creep and shrinkage [3].](https://www.bft-international.com/imgs/tok_e63d8d2a031761aa4823bba261ed1e59/w300_h200_x400_y210_103943853_706d6e3c84.jpg)