Parameters to Describe the Dynamic Characteristics of

Production Boards

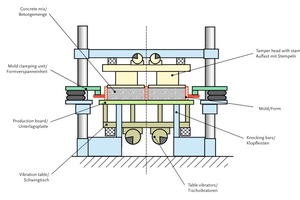

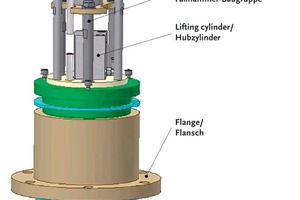

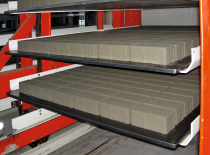

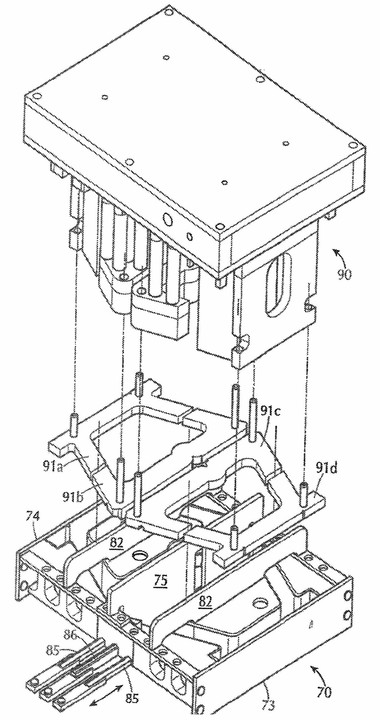

So-called board machines are used for the manufacture of the major share of concrete products in Germany and Europe. These are concrete block machines that mold and compact the items directly on production boards (or base plates) (Fig. 1). These boards are also used for the transport and storage of the products in high-bay racks until the layers are stacked upon each other.

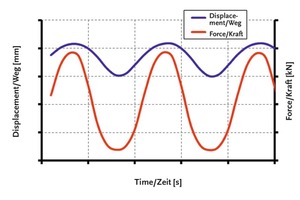

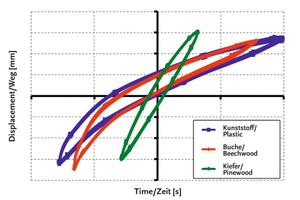

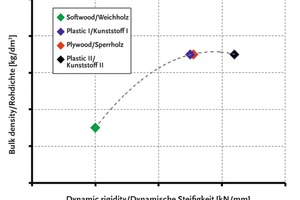

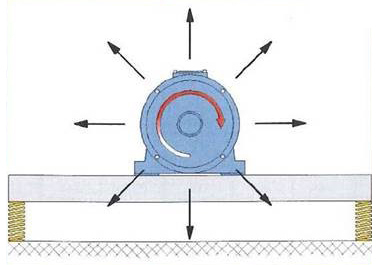

A very intense shock vibration process is normally used for the molding and compaction of the concrete mix. This method uses coordinated movements of individual subassemblies of the production system (working masses) to generate periodic impact sequences in defined intensities that are transferred into the concrete mix to be compacted via the molding subassembly. The production boards are part of the working masses of the block machine’s vibratory subassembly, which is a complex oscillation system whose design is of key importance with regard to the achievable quality of the concrete products....