The Use of Ecocement and Molten Slag in Japan

In Japan, about 5 million tonns of municipal solid waste is generated each year. In the past, municipal solid waste was buried in coastal landfills or disposal sites in valleys. However, these methods of disposal also resulted in environmental pollution, with the host of the problems caused by marine pollution, fly infestation, land pollution, river pollution and shortage of disposal sites. Moreover, the construction of new disposal sites could not catch up with the increase in solid waste. Against this background, new methods of municipal solid waste disposal were developed.

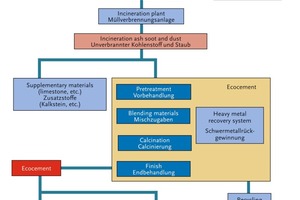

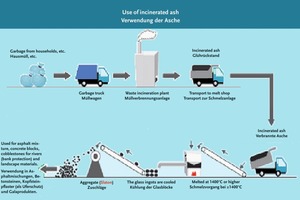

One of these is recycling the waste into Ecocement. This method uses the incinerated ash from the waste as a material for producing cement. Heavy metals contained in the ash are removed in the cement production process for reuse at refineries, or are otherwise treated safely.

The other method is melting and hardening the incinerated ash into slag. Heavy metals become difficult to be eluted when the ash is converted into slag. The slag can be used as concrete aggregate or as roadbed paving material.

Ecocement

Ecocement refers to cement that uses at least 500 kg of waste material, such as...