Automation of rebar tying in precast concrete factories

Max Co., Ltd. is currently developing a Rebar Tying Unit for Automation for the production lines of precast concrete factories. Normally, workers tie rebars using wires in precast products. This Rebar Tying Unit for Automation offers a solution to the labor shortage problem faced by factories and the pursuit of production efficiency.

Max Corporation‘s Mission

Max is a pioneer that launched the world‘s first battery operated rebar tying machine as a hand tool in 1993. Since then, it has been highly praised for improving productivity and reducing the workload.

One of the issues surrounding the construction industry in recent years is the decline in the number of construction workers. Against this background, the demand for precast concrete is expanding, and precast concrete factories will be required to further increase their productivity in the future. Max has provided hand tools, Rebar Tier to precast concrete factories, contributing to reducing the physical burden on workers.

The Unit currently under development aims to automate rebar tying work and improve productivity. By utilizing the knowledge and technology of rebar tying cultivated with hand tools, we will develop the Rebar Tying Unit for Automation and contribute to the further growth of the construction industry as a solution partner of precast concrete factories.

Concept of Rebar Tying Unit for Automation

The prototype currently under development utilizes the technology of hand-tool rebar tying machines that have been used in tying work sites for over 30 years. It is a dedicated tying terminal equipped with a large capacity of consumables, which reduces the time and effort of replacing consumables. In addition, by automatically recognizing rebar intersections through image processing and making it possible to handle multiple products without teaching, we aim to improve the efficiency of rebar tying work in precast concrete factories.

Specific features are as follows.

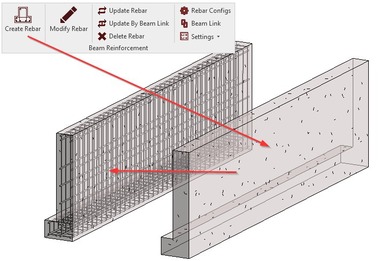

1. By attaching it to a robot arm, it can be used to bind flat objects such as ceilings, floors, and wall panels, as well as three-dimensional objects such as beams and culverts (it can also be attached to devices other than robot arms).

2. Two φ1mm wires are used to draw the rebars together and then twist them to bind them firmly.

3. The height of the knot is reduced to approximately 15mm by using technology to bend the wire tip.

4. Approximately 5,000 continuous bindings can be performed without changing the reel.

5. The intersection points of the rebars are detected by acquiring and analyzing images, so there is no need to input or teach the intersection points in advance.

6. It detects misalignment and obstacles in the rebars, and automatically adjusts the optimal position, angle, and stroke to bind them accurately.

7. The total number of bindings, machine status, remaining wire, etc. can be checked on the app.

Exhibiting at bauma

Max Co., Ltd. will be exhibiting at bauma, which will be held in Munich, Germany from April 7th to 13th. Booth number EWE.28 (Max Europe BV). There, we will exhibit the latest Rebar Tying Unit for Automation, which is currently under development, and demonstrate tying.

CONTACT

Max Europe BV

Antennestraat 45

1322 AH Almere/Netherlands

+31-36-546 9669