Bespoke straddle carrier for bespoke drainage solutions

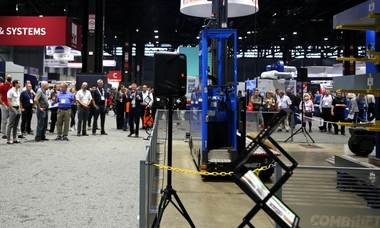

JKH Drainage was established 53 years ago and the founder’s grandson, MD Daniel Prince, is now in charge at a new 6 acre site in Suffolk which will give the company the capacity to grow and take on larger projects. A key piece of equipment to cope with the increased volume of raw materials and finished products is a 35t capacity Straddle Carrier from the Irish manufacturer Combilift.

“Growth this year was at around 30% and we expect this to continue due to infrastructure projects such as rail links, road improvements and a boom in housing construction,” said Daniel. “These generate increased demand for our products which we like to call ‘offsite solutions for onsite problems’. Together with our partner Althon, we supply standard and bespoke precast concrete products such as underground drainage chambers, headwalls and outfalls for pipes as well as gratings and steelworks to customers across the UK.”

During the planning stages for the new site, Daniel and his team looked at options for handling the heavier and bulkier products when they are demoulded inside the casting facility. These currently weigh around 8.5t, but will soon increase to 12t in a single cast, so extra lift capacity needed to be factored in to new equipment. Gantry cranes were initially considered but quickly discounted as they would have taken up too much of the already limited vertical space.

High level of versatility indoors and out

“We can move smaller, standard castings with our regular forklifts,” said Daniel, “but once you get above around 6t, or for bespoke oversized products that can have a footprint of 2.5 x 4m, this gets problematic as load stability becomes an issue. We therefore investigated the potential of a Combi-SC straddle carrier, and as each unit is bespoke we liaised closely with Combilift engineers to come up with the best specification for our machine according to our specific requirements.

With a telescopic facility, the SC’s closed height of 5.5m enables it to pass through the 5.8m high doorway, with just enough clearance in the 6m roof space to lift the largest castings and take them to the outside storage areas. Chains can be connected to various points on the two side shifting beams mounted on the top of the frame and the full open telescopic height of 8.1m offers plenty of room for castings to be rotated and set down at the most suitable storage angle. JKH chose a remote control model which offers good all round visibility for one operator without the need for banksmen. Diesel power was considered the most suitable as the Combi-SC spends around 75% of its time working outdoors across the extensive site.

“The Combi-SC has provided us with a high level of versatility indoors and out, as well as when we need to load products onto trailers for customer delivery,” said Daniel. “At 1.8 acres, our old site was much smaller, and the extra space represents a vast increase in business opportunities. We currently manufacture around 50t a day, and we wanted to future proof our handling procedures from the outset here, and this is exactly what we have done with Combilift’s expertise.”