Safely delivered to the customer

The German brochure "Ladungssicherung von Betonprodukten auf Straßenfahrzeugen" (Load securing of concrete products on road vehicles) has been published this year. In an interview with the editors of the BFT International trade magazine, the co-author Dipl.-Verwaltungswirt (FH) (graduate in public administration) Alfred Lampen explained the special conditions to be considered for the transportation of beams, floor slabs or paving blocks and which basic information everyone must have on the securing of load.

BFT International: On behalf of the German Association for the Concrete and Precast Industry North, ConcreteComponents Bavaria within the Bavarian Association of the Quarry and Pit Industry, Baden-Württemberg Association of Concrete and Precast Plants and the Entrepreneurs' Association of Mineral Building Materials (UVMB), you have written the brochure "Load securing of concrete products on road vehicles" together with technical expert Ralf Schöne. Why became such a brochure necessary?

Alfred Lampen: Especially, the precast concrete industry is offering a wide range of different products, starting with the large precast elements through to the paving blocks on pallets. Each of these products needs to be secured in an individually appropriate way.

There is a great number of opinions, reports and surveys on how to do this. With the objective to give uniform and clear recommendations on load securing of the different precast concrete elements, we have tried to take all these opinions, reports and surveys in the new brochure into account.

BFT: What is the technical and legal basis of these recommendations?

Lampen: They are based on the German VDI 2700 series of guidelines and supplements, the European calculation standard DIN EN 12195-1 and special surveys which were already available on the topic including values determined by Fraunhofer Institute, TÜV or Dekra.

BFT: Which are the basic principles on load securing every forwarder and driver must know?

Lampen: As a general rule, load is considered to be secured adequately if the effect of the load's mass force is compensated by the interaction of frictional force and securing force. Therefore, forwarders and drivers need to know the following correlations:

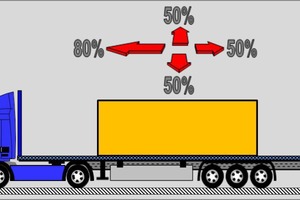

First of all, they need to know that 80% of the weight of load have to be secured towards the front and 50% of the weight of load each towards the sides and towards the rear.

Secondly, they need to know that a certain percentage of load securing is already effected by the friction between cargo and loading surface. For this purpose, the forwarders and drivers must know the respective coefficient of friction of two-dimensional building components, bar-shaped components, manholes, palletized concrete products and so forth acting on the respective loading surfaces. The brochure contains tables and information in this regard.

BFT: Can you give us an example.

Lampen: Let's assume that you use a flat-bed truck for transporting several two-dimensional precast concrete elements with an overall weight of 10 tons which are stacked up on each other and there is no form fit towards the front. You must secure 80% of the load weight towards the front, that is 8 tons. The force of the friction between the precast concrete element and the steel loading surface reduces the mass force; this corresponds to a coefficient of friction of 0.4; which means that no longer 80 % of the load weight have to be secured, but 80 % minus 40 % that is only 40 % or in our example 4 tons.

The remaining difference resulting from mass force minus frictional force has to be compensated by securing systems such as lashing straps and lashing chains, stanchions or board walls.

Which securing system you need and how much of the same requires an even more complex calculation. On this subject, you will find short overviews which we have compiled on the basis of the VDI guideline 2700 sheet 2 and the calculation standard DIN EN 12195-1.

BFT: Let us have a look at the five product groups which you differentiate in the brochure and the specific recommendations you respectively provide on secure loading of the same. This starts with the two-dimensional building components, such as floor slabs and wall elements – what are the key issues?

Lampen: The transportation of two-dimensional building components by means of an inloader, A-frames or inclined frames does not cause any problems.

However, horizontal transportation may cause problems if several two-dimensional building components such as floor slabs are transported without form fit towards the front. This means that floor slabs placed on the loading area without form fit towards the front require very high securing efforts.

However, the floor slabs may be damaged if a lot of lashing straps are used to secure them. Therefore, it is not unusual that the forwarders and/or drivers use fewer lashing straps than being appropriate according to the calculation of the standard. Unfortunately, in this case the load is not secured sufficiently.

To place several two-dimensional building components on top of each other in such a way that their edges are flush towards the front in the direction of travel is therefore of advantage. Then I can secure the stacks by means of stanchions or head slings towards the front.

BFT: What has to be considered in case of bar-shaped components, as columns, beams, joists or cross members, for example?

Lampen: The transportation of bar-shaped components most often is carried out by heavy-load vehicles with stanchions or trailers. All in all, this is organized quite well.

A particular case, which we have included in the brochure in this product category, are staircases. They are partly shaped in such a way that load securing for transportation is very difficult. The forwarders and drivers often just throw some straps across and lash them down. By way of calculation this is often insufficient because lashing them down is not effective owing to the flat lashing angle.

We recommend rope slings as load securing of staircases. The rope slings are used for diagonal lashing. For example, four lashing straps applied diagonally and an additional strap lashed down are sufficient for the load securing of staircases weighing up to 5 tons.

BFT: What has to be considered for the transportation of manholes, pipes and molded parts?

Lampen: Manholes are predominantly transported in an upright position. They must be blocked towards the front by means of stanchion systems or head slings, for example. In addition, they must be lashed down in order to prevent shifting on the loading area.

Pipes are transported on the loading area in a lying position. It is imported that the load is form fit towards the front and to the sides. Again stanchion systems or slings have to be used here. The principle is always the same.

BFT: Palletized building components presumably account for a large part of road transport. Which are the challenges in this case and which solutions do you provide?

Lampen: In case of palletized cargo we are faced with two main challenges: First of all, there is a large number of different pallets available and the loaded pallets have different weights. As a consequence, it is often not possible to make use of the entire loading area, not allowing form-fit loading – either the dimensions of the pallets do not fit or the vehicles would be overloaded by the overall weight of many heavy individual pallets. Hence, the forwarders or drivers leave gaps between the individual pallets.

Secondly, many forwarders and drivers use a crane and clamp for loading. If they use a clamp for loading, then there is a gap between the pallets as well.

We suggest pallets with a standard size – namely EUR-pallets measuring 120 x 80 cm, EUR-2-pallets measuring 120 x 100 cm or industrial pallets measuring 120 x 120 cm. You can always place two of them side by side, thus coming up to the width dimension of the load of 240 cm and providing for form-fit loading to the sides.

Furthermore, we recommend reducing the weight of the individual pallets, so that the loading area is entirely used without overloading the vehicle.

And finally, we recommend using a crane with fork for placing the pallets on the loading area close-packed together; in this way you avoid gaps which inevitably arise when loading the loading area with the aid of a clamp.

If you adhere to all of these recommendations, then the board walls of the vehicle secure the cargo and you do not have to take any additional securing measures.

BFT: It is also important for the securing of load that the vehicle structure is perfectly intact, that board walls, lashing points or even the plates of an inloader trailer are fully stable according to the specifications. Is visual checking by the forwarder and driver before transportation sufficient?

Lampen: Yes, it is sufficient. They walk around the vehicle and look whether the board walls are intact, whether the locking system of the rear door is working, whether the plates are really exerting pressure or whether they are just loosely leaning against the precast element. If everything apparently looks okay, I can document this, thus minimizing the organizational culpability of the forwarder.

BFT: And how do I have to document so as to be on the safe side if the worst comes to the worst?

Lampen: As individual as possible, because in case of legal proceedings I have to prove that the very loading that is concerned was secured adequately.

So I carry out a visual check and make a note on every detail, whether it does exist and whether it is in good working order. For this purpose, we have conceived a template that is shown on page 35 of the brochure. Every company can adapt this template to the individual needs. You stamp the template on the delivery note and on the copy and tick off the stamped box "anti-slip mat used – yes", for example.

If the worst comes to the worst, you can present the copy of the delivery note to the court.

BFT: How do you assess the chances that the recommendations of the brochure "Load securing of concrete products on road vehicles" will gain acceptance in the industry in the medium term?

Lampen: In my opinion, the chances are good. Some forwarders have already changed their systems. And others will follow.

Above all I believe that it shows a great sense of responsibility that the industry has decided to have such a brochure produced. And I would be very glad if the companies in the industry would check the recommendations concerning the securing of load without bias and select what suits them best.

Interview: Christian Jahn, M. A.

CONTACT

Verband Beton- und Fertigteilindustrie Nord e. V.

Raiffeisenstraße 8

30938 Großburgwedel/Germany

+49 5139 9994-30