Innovation: Non-waste wax formwork

The Institute of Structural Design (Institut für Tragwerksentwurf, ITE) of the Braunschweig University of Technology is the winner of the Innovation Prize of the Supplier Industry for Structural Concrete Products 2017. The prize was awarded for the development of an innovative precision formwork made to 100 percent of recyclable industrial wax. The award ceremony took place during the opening of the 61st BetonTage convention on February 14, 2017 in Neu-Ulm.

Formwork units made of different materials such as timber or rigid foam have to date been used for the production of geometrically complex structural concrete elements. These materials have several disadvantages: there are significant deviations from tolerance limits, and they are usually not recyclable but frequently even need to be disposed of as hazardous waste.

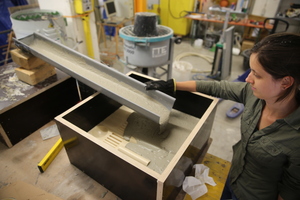

Through cooperation of the Institute of Structural Design and the Institute of Machine Tools and Production Technology (Institut für Werkzeugmaschinen und Fertigungstechnik) of the Braunschweig University of Technology within the parameters of Priority Program 1542 of the German Research Foundation (Deutsche Forschungsgemeinschaft, DFG), the experiences acquired in free-form formwork and concrete construction were merged with those gained in the manufacturing and automation technologies of machine engineering. In the process, a formwork technology was developed that enables structural concrete products of virtually any geometric design, including highly complex ones, to be manufactured with maximum economic efficiency and utmost precision.

Freedom of design, recyclable

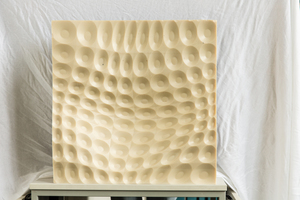

The so-called “non-waste wax formwork” uses industrial wax as shaping material which can be processed very quickly, to a high degree of precision and with considerable freedom of design through CNC machining. In addition, the wax can be fully returned to the material cycle by melting it down, thus optimizing material expenditure and eliminating waste production. Since the wax can be recycled, the submitted production technology represents an economical and ecological production process for customized free-form concrete products.

“For the first time, with the non-waste wax formwork, we have developed a method enabling us to manufacture high-precision free-form concrete products in an economical and ecological production process. At the same time, the industrial wax can be reused completely by melting it down,” says Prof. Dr.-Ing. Harald Kloft from the Institute for Structural Design.

The Innovation Prize of the Supplier Industry for Structural Concrete Products is offered annually by FBF Betondienst GmbH, host of the BetonTage convention, and BFT International. The prize is awarded to exemplary innovative products, processes and services offered by the machine, software and supplier industry of the precast concrete sector. Important selectioncriteria for the award include the level of innovation and the originality of the proposal, its relevance for the precast concrete sector, its market and application potential, as well as the consideration of technological standards.

CONTACT

Technische Universität Braunschweig

Institut für Tragwerksentwurf

Pockelstraße 4

38106 Braunschweig/Germany

+49 531 391-3571