Synthetic fiber reinforced precast elements in infrastructure building

The use of precast elements in the infrastructure construction sector is not really new. For many years, relatively small components have been used for manholes, sewers, and slabs designed to carry vehicle traffic for slab track systems – as have larger elements for tunnel construction, such as tunnel segments. The reason for this is obvious: precast elements are manufactured in production halls under strict, uniform conditions, thus ensuring consistent quality. This is virtually impossible to achieve with in-situ construction – owing to weather influences alone.

Increasing numbers of structural components are now being prefabricated. One problem here is frequently the complex reinforcement involved. A structural member must often carry high to very high loads, requiring correspondingly high quantities of steel reinforcement. Reinforcing cages, at least the majority, are prefabricated as well; installing them in the forms is anything but simple. The frequently enormous weights encountered require the use of cranes. Standards specifying concrete cover must be observed to prevent subsequent corrosion, and the required time is enormous.

The durability factor

Complex reinforcement work is not the only challenge facing precasters: the complexity of preceding logistics efforts should also not be underestimated. The reinforcing elements must be made available in the right quantity at the right time – all of which must be coordinated with production. The reinforcing elements are placed in intermediate storage, in the factory yard, in accordance with their size. One following necessary logistics step is their being placed in readiness in the production hall – which, in turn, again requires time. In addition, parts damaged during demolding must be expertly disposed of or expensively repaired – which also give rise to considerable cost.

But the manufacture of conventional reinforcement is not the only worry of manufacturers and of the builders they supply. Reinforcement durability has been the be-all and end-all for many years. Calculations based on well-known standards have long been applied to provide the basis for reinforcement, and extensive tests have ensured that the necessary energies could safely be assumed during loading. These tests, however, are referenced to the present, and ultimate load tests are usually performed only after 28 days. But precast elements remain in service for years and decades: for example, as tunnel segments, manholes, and sewer structures. And this is where the durability factor becomes critical. Aggressive wastewater takes a heavy toll on conventional steel reinforcement, and strength values that are attained and tested after 28 days are nothing more than a wish from the distant past, after decades of service.

Creep test passed

This is the reason why manufacturers and developers use high-performance synthetic fibers that are demonstrably capable of replacing or massively reducing the use of steel reinforcement. A number of years ago, the Swiss Road Construction Agency (ASTRA) commissioned a comprehensive test covering the durability of synthetic fibers. The synthetic fibers achieved very high ratings, owing to the widely known fact that plastics do not corrode.

Moreover, in addition to durability, the post-crack behavior of an element under ultimate loading demands consideration. High-quality fibers are capable of absorbing the transferred energy. And only fibers of very high quality will pass a creep test: following artificially initiated rupture fracture, the test specimen is subjected to defined residual loading, upon which the fibers, which bridge the rupture, are subjected to continuous loading. These so-called creep tests – which are in Austria, for example, prescribed in the Austrian Guideline “Fiber Reinforced Concrete” – specify that only fibers be used that have been demonstrably tested by an external, independent testing institute over a period of at least a year and a half. Until now, only the bi-component Concrix macro fiber, developed by the Swiss Federal Laboratories for Materials Science and Technology (EMPA), has not merely passed the test, but has also demonstrated its superior qualities far beyond all requirements. Only minimal deformations occurred even after four years of continuous post-rupture loading.

Use in pressurized water pipes

More and more precasters have now come to use the bi-component Concrix fiber made by the Swiss company Brugg Contec. Figure 1, for example, shows high-pressure water pipes that were manufactured for the Rhone Oberwald power plant. A GRP pipe 51 mm thick, 6 m long, and 3 m in diameter was provided with an inner concrete shell, 12 cm thick and reinforced entirely with plastic fibers. The dosage is 4.50 kg/m3 Concrix ES; it is based on structural-engineering calculations based on applicable standards.

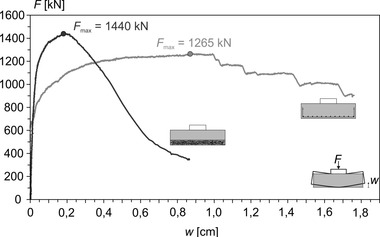

Another example is precast slab elements for logistics areas that until recently had been reinforced with two layers of wire mesh reinforcement (Figs. 2 and 3). Calculations have shown that the reinforcement can be replaced with Concrix ES doses of 3.0 to 4.5 kg/m3, depending on the thickness of the slabs and the loading. The Dutch manufacturer has verified this application in loading tests performed on completed elements, and now uses high-performance synthetic fibers from Brugg Contec.

Interested parties can obtain additional information and structural-engineering calculations for members from the engineers at Brugg Contec (see CONTACT).

CONTACT

Brugg Contec AG

Gübsenstrasse 80

9015 St. Gallen/Switzerland

Tel. 071 466 12 12

info@bruggcontec.com

www.bruggcontec.com