Automated handling of concrete elements using wire robots

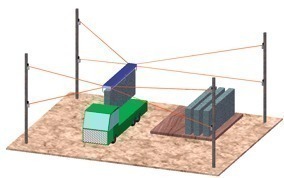

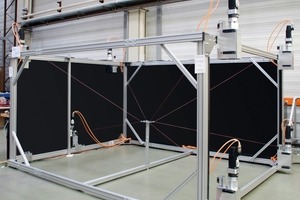

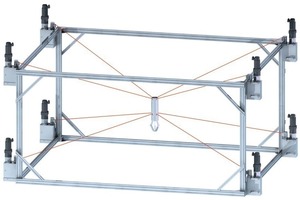

● The handling of large and heavy elements, for example during production or dispatch, is a time-consuming process that can often not be automated. Each element is moved separately when using crane systems. Automation designs used for the manufacture of smaller products are not appropriate in this case. By contrast, wire robots can offer a feasible solution. Unlike a conventional industrial robot, a wire robot moves a product by the coordinated operation of several winches the routes of which merge in the gripper system. Wire robots are highly scalable in terms of their size and lifting load, which makes it possible to also install wire robot systems that extend over the entire factory building and carry loads of up to several tons. Wire robots add value because of the precision of their motion, which can be automated. They thus provide the basis on which new logistics concepts can be developed. A robot prototype is currently being tested at Fraunhofer IPA.

Initial situation

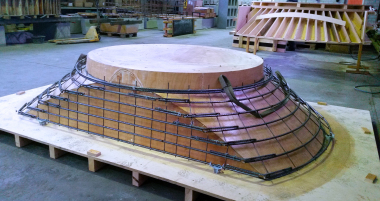

The transport of products or components in a manufacturing or dispatch environment is a process that does not add any value, which particularly applies to large, heavyweight elements. On the other hand, this process is time-consuming and requires a sophisticated infrastructure. Cranes are normally used for such lifting operations. Yet they can hardly be automated, which is due, on the one hand, to the gripping or fastening process that is specific to each component, but also results from the swaying motion and the non-defined orientation of the component.

A handling system...