Swiss reinforcement manufacturer

once again invests in robot technology

Fischer Rista AG, one of the most modern, most innovative and most efficient companies of Switzerland‘s reinforcement industry, has been pioneer in automation of production proc-esses for many years now. As a subsidiary of Fischer Reinach AG, a family-run company specialized in metal working with a 175-year history, Fischer Rista is constantly investing in new technology in order to increase efficiency, production speed and accuracy even more.

The company located in Reinach in the canton of Aargau is specialized in the production of complex reinforcement and innovative reinforcing systems. Reinforcement cages and earthquake resistant stirrup systems are part of the portfolio as well as punching shear reinforcement for building construction. “We are manufacturing in the range of industrial tolerances,” says Rolf Reichert, production manager. Therefore, the products have to be manufactured with extremely high accuracy. “This can only be achieved in highly automated production processes,” Reichert states.

Automation to increase the value added

This demand on an industrial production process, but not handcrafted workmanship, was the crucial factor for Fischer Rista to invest once again in automation. Once they had already started to modernize the wire mesh production in several stages seven years ago, using robotic units for automation, the stirrup production line and product handling should now be adapted to the special needs of the company by means of a new machine and a removal robot. “We aimed at increasing the value added per worker while reducing cycle times simultaneously,” production manager Reichert summarizes.

As already in the past, Progress Maschinen & Automation, a company of the Progress Group, was chosen as partner. “The decision was taken after an evaluation process with several suppliers,” says production manager Reichert. The actual production concept was conceived by Fischer Rista. “For us it was exciting to see which supplier implemented this concept and in which way,” Reichert continues. “An optimum integration of the robotics into the complete system was finally decisive for us to collaborate with Progress again.”

Production of stirrups and bars

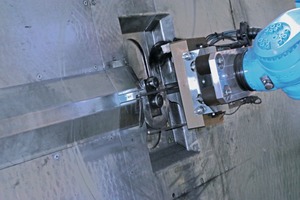

The system installed consists of the Pluristar 3D multifunction machine and a fully automated removal robot. The Pluristar 3D is used for the production of stirrups and bars from coil with diameters between 6 and 16 mm. The machine is not only a stirrup bender, but also straightening, cutting and double-bending machine in one. Therefore, the machine can be used in a flexible and efficient way. Along with open and closed stirrups and bars with bending, the 3-D bending system also allows the production of three-dimensional stirrups in various shapes.

If it was previously necessary to remove the products manually, this work is carried out by a newly developed removal robot now. The robot removes and picks the finished stirrups in a precise and program-controlled way. For this purpose, the stirrups can be turned as well as placed next to or on top of each other. Flexibility plays an important role: the robot is in the position to remove stirrups in various shapes and sizes without special grippers or program changes.

Positive effect on production flow: automated order picking

The concept of automated removal has an extremely positive effect on the production flow, according to production manager Reichert. “The robot allows us to optimize the cycle time and the material handling considerably.” The possibility of automated pre-picking of the products is particularly important, according to him: “Since we partly further process the stirrups and bars as 3-D structures, order-picking has to be fast and with zero error rate.” The automation of these work steps not only minimizes the physical burden, but also increases occupational safety.

Reichert sees Fischer Rista on the right track. According to him, the two conflicting trends of quantity against quality became stronger and stronger in the reinforcement industry. “Many companies rely on tons, while others on special products. We, for example, fully concentrate on specialized 3-D reinforcement, for which we need high precision and high repeating accuracy which is guaranteed by the Progress equipment.”