Design concept and flow properties of SCC – Part 2

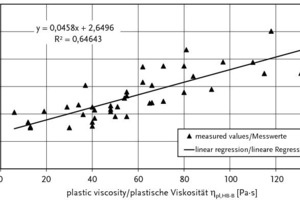

The first half of this two-part article presented an approach to determining the volume of the cement paste required to produce SCC whilst considering the granulometric characteristics of the aggregate mix. On this basis, the second part deals with the mix design and the flow properties of SCC of the powder type. Starting from the required amount of cement paste determined in tests, the concept for the design of powder-type SCC mixes is introduced. Moreover, the fresh concrete characteristics of the SCCs produced according to this design concept are examined. In this regard, the article concentrates on describing the flow properties documented during the slump test and the correlation to the plastic viscosity measured in the rheometer.

Powder-type SCC mix design

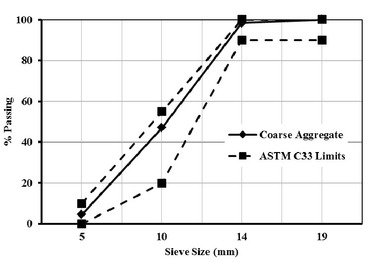

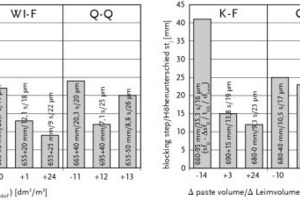

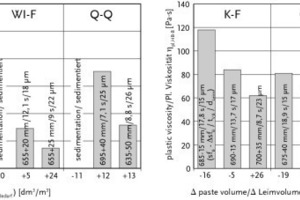

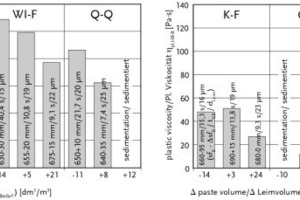

To produce the SCCs under study, the above-described aggregate mixes consisting of gravel and fluvial sand (K-F), quartz porphyry chippings and fluvial sand (Q-F), shell limestone chippings and fluvial sand (WI-F) and quartz porphyry chippings and crushed sand (Q-Q) were used with a ratio of particles smaller than 4 mm in size that amounted to approx. 50 percent by mass (ABB 16 grading curve). The mix was determined using the known material volume calculation by defining the cement paste volume and the volume-related cement/additive and water/powder ratios (VW/VM)....

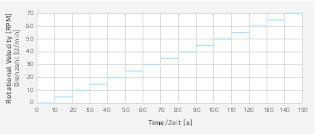

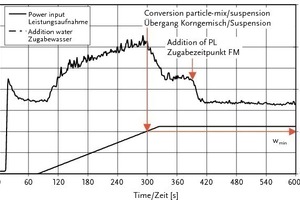

![Fig. 1 Schematic representation of the “shear resistance” of an aggregate mix depending on water content. In this diagram, the minimum water amount wmin characterizes the conversion of the particle mix to a suspension (taken from [6]).](https://www.bft-international.com/imgs/tok_f42c9f4cad7e10b6e869e95bd1279fe2/w300_h200_x400_y244_103937946_cd3ee92e88.jpg)

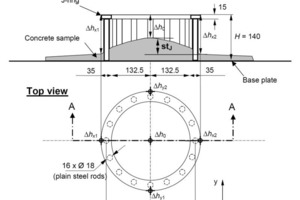

![Fig. 4 Photograph and drawing (taken from [12]: abrams cone put overhead by the author ) of the setup to measure the difference in height within/outside the J-ring (stJ).](https://www.bft-international.com/imgs/tok_7f56a32f839cf942072854b3bf977bef/w300_h200_x400_y300_103937999_6aee9100a8.jpg)

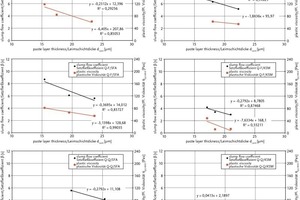

![Fig. 8 Flow curves recorded during the slump test in accordance with the SCC Guideline [2] for the SCCs with gravel/fluvial sand (K-F), quartz porphyry chippings/fluvial sand (Q-F), shell limestone/fluvial sand (WI-F) and quartz porphyry chippings/crushed sand (Q-Q) when varying the paste volume with (d,J) and without (d) blocking ring. Time recording started when the slump diameter reached 400 mm. Concrete additiion CFA.](https://www.bft-international.com/imgs/tok_a4236fb954bcfdc7fbf81836692fd8dc/w300_h200_x400_y238_103938005_bdc7c60e31.jpg)

![Fig. 9 Flow curves recorded during the slump test in accordance with the SCC Guideline [2] for the SCCs with quartz porphyry chippings/fluvial sand (Q-F) and quartz porphyry chippings/crushed sand (Q-Q) when varying the paste volume with (d,J) and without (d) blocking ring. Time recording started when the slump diameter reached 400 mm. Concrete additive: LSD.](https://www.bft-international.com/imgs/tok_2883b24920d31cc69a86d2c5ccfc421a/w300_h200_x400_y116_103937965_ca658d9751.jpg)