Photocatalytic Concrete in Color

Interest in using environmentally compatible materials for new construction projects and for the renewal of existing projects is increasing rapidly, both from private and public sector customers. One of the more novel materials with environmental benefits has been the innovation of photocatalytic building products, such as glass, coatings and more recently, photocatalytic concrete.

Products made of photocatalytic concrete are mainly achieved by cements that are doped with photocatalytic titanium dioxide, therefore only white and grey products are commonly available. There is interest and demand for colored products for aesthetic reasons, but until now, the technology for colored photocatalytic concrete did not exist. The supposition that adding standard inorganic color pigments to photocatalytic concrete may reduce or eliminate the photocatalytic activity has already been disproved (see BFT 12/2009) – but could inorganic pigments themselves be modified to enable the manufacturing of colored photocatalytically active concrete products?

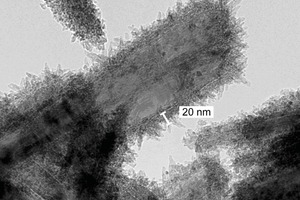

To answer this question, the coloring effect of Iron Oxide Pigments has been combined with the photocatalytic activity of TiO2. A method was developed to create a stable Iron Oxide/TiO2 compound (Fig. 1) in cooperation with the University of Turin (Department of Inorganic Chemistry). Through this method, the whole color range of yellow, red and black photocatalytic Iron Oxides is created.

The following typical properties of colored photocatalytic concrete have been determined in extensive trials for these new pigments: Air Pollution (NOx abatement), Self-Cleaning, VOC Reduction and Influence on Microbiological Growth.

Air Pollution

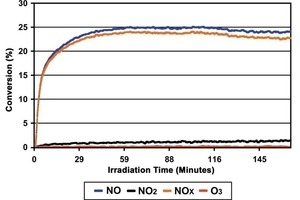

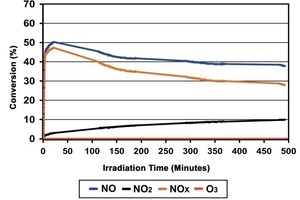

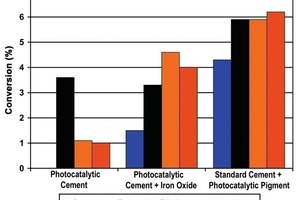

Tests were conducted to measure Nitric Oxide (NO) reduction according to ISO 22197-1:2007 and UNI 11247:2007 (Fig. 2 and 3).

Two concrete blocks were prepared at equal Iron Oxide Pigment dosage. The block made with standard cement and photocatalytic pigment has a lower initial NOx conversion rate and a constant result over time, whereas the block made with photocatalytic cement and standard pigment shows a higher initial rate and a degradation of activity over time. Also the production of NO2, another air pollutant is remarkably lower for the block made with photocatalytic pigment.

Self Cleaning

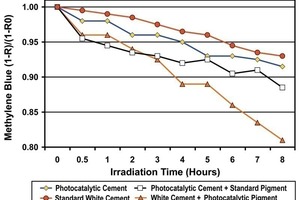

Methylene Blue, a commonly used dye for the determination of self cleaning properties of photocatalytic materials (DIN 52980:2008-10, Draft Standard ISO/CD 10678) was sprayed onto concrete blocks and the dye degradation was measured over time under irradiation (Fig. 4).

The blocks made of standard cement and photocatalytic pigment showed a nearly total degradation of the dye after 8 hours whereas all other samples show lower degradation rates.

VOC Reduction

For this test, concrete blocks were exposed to an atmosphere containing Benzene (13.5 ppbv), Toluene (23 ppbv), Ethylbenzene (20ppbv) and o-Xylene (20 ppbv). The conversion (photochemical oxidation) of these components into harmless products is measured.

Fig. 5 shows that the photocatalytic pigment is the most active regarding the conversion of all four components. Photocatalytic cement alone is inactive regarding Benzene and less active for all other compounds. If photocatalytic cement is colored with standard Iron Oxide (in this case yellow), an increase of activity can be observed. This effect may be due to a synergistic action between the Iron Oxide Pigment and the TiO2 component in the cement and is seen to a greater extent when the Iron Oxide and the TiO2 are directly combined (as in the coloured photocatalytic pigment) instead of a simple physical blend of the TiO2 component and the Iron Oxide Pigment.

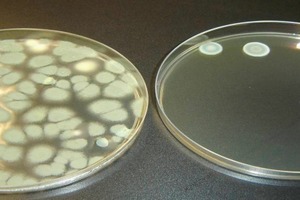

Influence on Microbiological Growth

In co-operation with the University of Turin (Department of Plant Biology), a study was initiated to test the inhibition of the germination of bacteria, yeasts and fungus by photocatalytic products in concrete and mortar applications. Fig. 6 demonstrates the degradation effect on mold growth.

Color

The above mentioned synergistic effect between the Iron Oxide and the TiO2 component can be observed also in the coloring properties. When used as an integral color in concrete, photocatalytic pigments demonstrate a more brilliant and stronger color. Photocatalytic pigments as presented in this article do not influence the final concrete properties. They are compliant to the applicable European Standard EN 12878 (“Pigments for the coloring of building materials based on cement and/or lime – Specifications and methods of test”) and marked “CE”.

Summary

This article presents a new range of functional inorganic pigments: Iron Oxides made photocatalytically active by coating with a thin layer of TiO2. Tests regarding NOx- and VOC-abatement, influence on microbiological growth and self-cleaning properties confirm the new pigment’s universal and constant photocatalytic activity, which make them an economically valid alternative to current photocatalytic materials.

www.rpigments.com