Precast Plant Dobler is Manufacturing with Strengthened Filigran EV lattice girders

Special building projects require special building elements. In the city of Kempten/Germany prehistoric remains of the St. Erasmus chapel shall be opened to the public as a show room. The underground space of this former chapel of the 12th century including the historic external walls should be spanned without using columns. The span required thus account for about 10 m to 13 m.

The engineering consultancy of Dr. Schütz Ingineure based in Kempten selected the static system and the dimensioning. The slab was chosen to be 34 cm thick and constructed as a semi-precast slab by Dobler GmbH & Co. KG, Kaufbeuren/Germany. In order to limit the deflection, prestressing elements were included for a subsequent bond. The slabs were manufactured as semi-precast Filigran floor slab. Parts of the floor slab were born on bore piles and protruded them. This required slab lengths of up to 15.3 m.

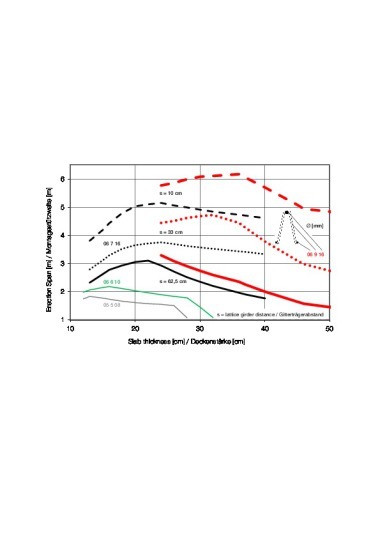

The transport and installation state of these extraordinarily dimensioned slabs had to be ensured. Dobler designed the precast elements with a thickness of 11 cm. Furthermore, Filigran Trägersysteme GmbH & Co. KG, Leese/Germany recommended the application of strengthened lattice girders having a diagonal diameter of 9 mm and an upper chord diameter of 16 mm. For these Filigran EV lattice girders there is the new German national technical approval Z-15.1-147 available. Due to the high load-bearing capacity of this new girder, it was possible to grant approval for moments and shear forces of up to 10 kNm and/or 7.7 kN per lattice girder at lattice girder heights of 18 cm up to 30 cm. These values are significantly higher than the permissible values of other lattice girders and can be used for ensuring larger installation spans and transport states.

Filigran lattice girders EV 26 – 6 9 16 with an overall height of 26 cm were selected for the application in Kempten. For a selected distance between the girders of 30 cm and an overall slab thickness of 34 cm an installation span of 4.75 m was calculated on the basis of the approval. Nearly fully use has been made of this value for the said building project. In addition to this, the cutting forces could also be taken up by the lattice girders due to transport by crane. This transport was realized by means of four almost quadratically arranged load fastening points at each slab end. The center of gravity of these load fastening points were roughly situated at the quarter points of the slab length. This arrangement made sure that the cutting forces in the slab for the above-mentioned installation span were not greater during the crane transport (Fig. 1) than during installation.

The slab having a width of 3 m and a length of up to 15.3 m covered an area of 45.9 m² and/or 51.9 m² taking into account the large excess lengths of steel of 1 m on both sides. The overall weight of a slab of up to 12.6 tons was transported and installed safely due to the application of strengthened Filigran EV lattice girder.