Use of Polymer-modified Concrete in Bridge Construction – Part I

In May 2010, a bridge of polymer-modified concrete (PCC) was opened to traffic in the German city of Jena. The application of PCC as structural concrete in practice was made possible by 15 years of research in this field. Concrete mix designs could be determined to meet the specific requirements and in conformity with the standards. Special knowledge is required in particular for calculating the long-time behavior of the structure. As no confirmed detail knowledge is so far available in this area, a bridge was chosen whose geometry was primarily derived under structural aspects and which is subjected to only low loadings. In addition, the factors for describing the long-term behavior were considered with a high safety margin.

Fundamentals and Problem Formulation

The research examined the modification of mortar and concrete under different aspects. In Germany, PCC (Polymer Cement Concrete) is generally used in composite components and rehabilitation works as well as in the manufacture of industrial screeds and in road surfaces. These modifications are commonly achieved with thermoplastics. Mortars/concretes modified with epoxy resin (Epoxy Cement Concrete = ECC) are a special group. For these, the polyaddition of the epoxy (EP) resins to solid resin takes place in parallel to the hardening of the cement.

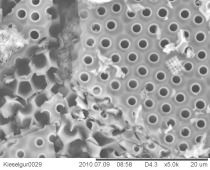

In the case of PCC, both the fresh and hardened properties of concrete are favorably influenced by the addition of polymers [1][2][3][4]. To obtain the positive properties of PCC in respect of mechanical parameters and durability, a formation of microfilms of the plastics in the cement-bound matrix is aimed for. Prerequisites for the film formation is a processing temperature larger than the minimum film formation temperature (MFT), conditions that enable water removal [5][6] as well as an adjustment of the reactivity, when using EP systems and cement [7].

The modification generally leads to an improvement of the resistance to freeze-thaw with and without de-icing salt. Requisite for this is an optimal structure, i.e. filming of the polymers [8]. It is assumed that hydrophobation has a similar effect [9]. Justness et al. [10] obtained with tests on ECC an increased freeze-thaw resistance compared to unmodified mortars. Inefficient polymer/cement ratios larger than 0.15 effectively increase the chemical resistance. Tu and Kruger [11] confirm the good resistance of ECC to frost-deicing salt and frost, resulting from the higher air content and the lower capillary water absorption.

The addition of plastics leads to an increase in the flexural tensile strength and a decrease of the modulus of elasticity. The compressive strength and the impact strength as well as the resistance to wear remain [12]. With plastics, pores can be lined, capillaries closed and spherical pores generated. This prevents the penetration of aggressive media into the concrete and results in a high resistance to chemicals as well as enhancing the resistance to freeze-thaw and frost-deicing salt. In [13], the effect of a styrene-butadiene dispersion is investigated. The action of organic liquids leads to a swelling of the dispersion particles. This was assumed to be the reason for the increased density. The PCC investigated were characterized by improved processibility and a relatively insensitiveness to curing. Investigations of the environmental compatibility of plastics-modified concrete were described in [14], without revealing any disadvantages.

Within the scope of the Junior Professorship Polymer Binders and Construction Materials as well as the research work conducted at the F. A. Finger-Institute for Building Materials Science [15 - 26], many of the results found in literature could be verified, numerous claims disproved or also more precisely defined. The suitability of PCC as a durable and sustainable structural concrete is a main focus of research of the Junior Professorship Polymer Binders and Construction Materials and was an element of several research projects sponsored by the German Research Foundation (DFG). Against this background, the first application of PCC as structural concrete for bridge construction could be realized.

For concrete structures, the decision on the type of concrete used is in increasing measure dependent on durability and economy. In this context, the sustainability, i.e. the assessment of the ecological and economical benefits, are gaining more and more significance. Bridge construction is one area of the building industry, where the sustainability of the construction plays a major role and where lack of sustainability regularly leads to property and financial damage. A major part of the costs is incurred during the useful life of a structure. Media aggressive to concrete and penetrating dampness in particular can lead to damage to the construction. Bridge caps are especially exposed members and have a shorter service life than the loadbearing structure. To prevent penetration of dampness and media aggressive to concrete into the loadbearing structure, bridge superstructures are commonly provided with bituminous sealing sheets, the installation of which is a complex task. This ensures the durability of the overall construction. These sealing sheets are not only expensive, they are also not very durable. Bridge caps must often be replaced after only a few years in service, and together with them the bridge deck. This leads to traffic obstructions, complex dismantling and reinstallation of the bridge equipment (passive protective equipment, such as bridge railings, and vehicle restrain systems) and is in every case connected with considerable costs. This contradicts the sustainability thought. To avoid these advantages, or to at least minimize them, all options for manufacturing a concrete that is as durable as it is dense and meets the requirements should be examined. One suitable possibility for this is modifying the concrete with plastics.

Description of the Structure

A frame bridge with a span of 2.5 m was chosen for the use of PCC in bridge construction. The bridge crosses an urban road and a creek. The new construction is a replacement of the original bridge so that the geometric conditions are not variable. The reason for the new construction was the poor state of repair and the limited bearing capacity of the original construction (Fig. 3). Due to the low construction height and the local conditions, a rehabilitation of the concrete members would have been a highly complex and difficult undertaking.

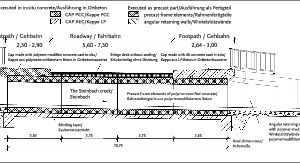

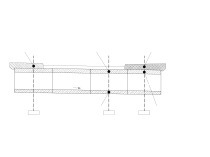

The construction (Fig. 2) is a closed precast frame with a clear width of 2.50 m and a clear height of 1.25 m. The wall thickness of the deck slab and every frame leg is 25cm, the roadway slab has a thickness of 30 cm. The arrangement of four precast frame members with a total length of 10,74 m allows modifiable lane widths from 5.55 m to 7,32 m. The caps arranged adjacent to the roadway have sidewalk widths ranging from 1.50 m to 3.00 m on the bridge structure.

The caps and wing cornices were manufactured monolithically in in-situ concrete. For reference purposes, always one cap each was manufactured in polymer-modified concrete and one cap in conventional air-entrained concrete.

The target properties summarized in Table 1 were used as the basis for determining the concrete composition.

The following structural particularities were realized:

» No sealing on the roadway,

» Installation of a range of sensors in exposed places of the structure,

» Dual execution of caps and wing cornices – one side in normal concrete and one side in polymer-modified concrete.

In this way, the special properties of PCC are exploited and an estimation of the PCC compared to normal concrete ensured during the service life of the bridge. The specific hardened concrete parameters of the PCC were determined in the laboratory and taken into consideration for the calculation of the structure. Fig. 1 shows the new construction that replaces the original bridge across the Steinbach creek.

Constituent Materials

At first, polymer-modified concretes were developed in the laboratory. The concretes were basically suitable for use as bridge construction concrete (Table 2) and bridge cap concrete (Table 3). For these investigations, materials in common practice were used.

In order to meet the requirements made on the strength, the precast members and the wing walls, a CEM I 52,5 R was chosen and for the bridge cap a cement of lower strength class (CEM I 32,5 R).

The aggregate sizes used are commercially available unbroken aggregate sizes with a grading curve in a favorable range and a maximum particle size of 16 mm.

To modify the concrete, an aqueous, 50 % dispersion based on styrene acrylic acid ester was used. The water content in the dispersion was taken into consideration in designing the mix. The polymer content of the concrete was 10% relative to the cement content. For the polymer-modified cap concrete, no additional air voids were introduced for attaining the resistance to frost-deicing salt.

Based on the results of the laboratory tests, the constituents of the concrete plant that was the cooperation partner were used in the production of the precast members and in the manufacture of the in-situ concrete cap. The aggregate, the cement and the superplasticizer used differed from the constituent materials used in the laboratory tests. The resulting compositions are presented in Tables 4 and 5.

The density of the fresh concrete, its air content and the temperature were determined immediately after mixing. The slump was measured ten minutes following the addition of water. The slump of the cap concrete mix was additionally measured 60 minutes later to take the transport time into consideration. The tests were performed in accordance with DIN EN 12350. The fresh concrete parameters determined for the precast concrete are presented in Table 6, those for the cap concrete in Table 7.

The test specimens were stored in accordance with DIN EN 12390 - 2, Appendix NA. The parameters of the hardened concrete were determined after 28 days. The compressive strength test was conducted in accordance with DIN EN 12390 - 3 and the static modulus of elasticity as specified in DIN 1048 – 5. The hardened concrete parameters of the concretes used are presented in Tables 8 and 9.

The investigations on the fresh and hardened concrete show that the results are reproducible also with changing constituents and that it is possible to reliably obtain the PCC projected.

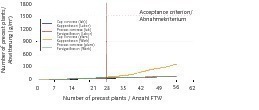

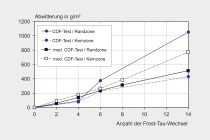

The check for the frost resistance and the resistance to frost and freeze-thaw with de-icing salt of the concretes was carried out in accordance with the BAW code of practice “Frost test.” This test prescribes the CDF test to demonstrate the freeze-thaw resistance and the CIF test to demonstrate the resistance to freeze-thaw [27].

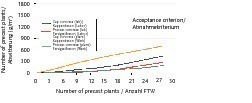

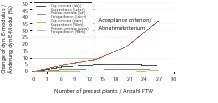

In the CDF test, the resistance to the freeze-thaw cycle is tested in comparison to the resistance of freeze-thaw under the action of de-icing salt. CDF stands for “Capillary suction of Deicing chemicals and Freeze-thaw test.“ The acceptance criterion for the CDF test is the amount of scaling per unit area. If the scaling after 28 freeze-thaw cycles < 1500 g/m², the concrete can be classified as being resistant to freeze-thaw and deicing salt. The acceptance of the dynamic modulus of elasticity is an additional acceptance criterion. The concrete is regarded damaged when the dynamic modulus of elasticity has dropped by more than 25% after 28 freeze-thaw cycles.

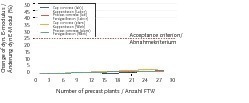

With the CIF test, the resistance to freeze-thaw is investigated using pure water. CIF stands for “Capillary suction, Internal damage and Freeze-thaw test.” The acceptance criterion for the CIF test is a decreased dynamic modulus of elasticity. The concrete is regarded damaged when the dynamic modulus of elasticity drops by more than 25% after 28 freeze-thaw cycles. An additional acceptance criterion is the amount of scaling per unit surface area. If the scaling < 1000 g/m² after 28 freeze-thaw cycles, the concrete can be categorized as frost-resistant.

The results of the CDF and CIF tests are presented in Figs. 4 to 7.

It can be seen that the acceptance criterion for the CDF test and the CIF test are fallen below, both for the laboratory concrete and the plant-manufactured concrete. Accordingly, the concretes can be categorized as freeze-thaw resistant and as resistant to frost-deicing salt. The reproducibility of the results is ensured also for these investigations, despite the varying constituents.

Summary and Outlook

In connection with the replacement of the bridge structure on Schreckenbachweg across the Steinbach creek in the German city of Jena, the researchers at the Bauhaus University in Weimar were given the opportunity to verify the positive properties of polymer-modified concretes in practice. Not only the actual bridge structure was manufactured of PCC, but a bridge cap as well.

The project could be implemented thanks to the innovative spirit and the support of the city of Jena. The construction is a precast closed frame with a clear width of 2.50m and a clear height of 1.25 m. Caps and wing cornices were manufactured monolithically with in-situ concrete. For reference purposes, always one cap each was manufactured of polymer-modified concrete and one cap each of conventional entrained-air concrete. The polymer-modified concrete was manufactured with a polymer content of 10% related to the cement content. The requirements made on the concretes were determined on the basis of the construction and the exposure and were checked in the laboratory. A comprehensive monitoring system was built into the bridge. In this way it will be possible to observe and evaluate the behavior of this innovative construction material in day-to-day use.

In the upcoming second part of this report, the experiences gained during the manufacture of the precast members and the in-situ concrete will be presented, as well as first results of the monitoring of the structure with the monitoring system.