Use of polymer-modified concrete in bridge construction – Part 2

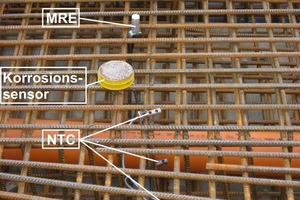

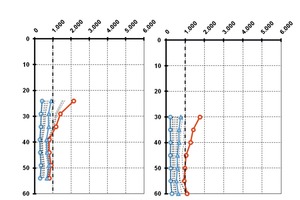

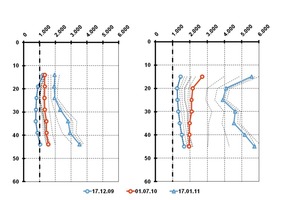

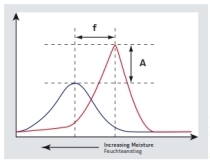

In May 2010, the first bridge made of polymer-modified concrete (PCC) was successfully accepted; basic research transferred to application in practice. The bridge made of polymer-modified structural concrete was created in close collaboration with the client, planners, scientists and contractors. The project aims to increase durability and minimize maintenance expenditures. The control and assessment of the PCC in practical application is supported by measurement technology. The mix design of the PCC, a description of the structure as well as the most significant results of the construction material tests of the concrete used are covered in the first part of this report. This second part deals with the manufacture of the precast elements and the cast in-situ concrete for the bridge caps. First results of the measurements performed on the bridge are here presented.

Manufacture of the precast elements

The PCC was conceived by the staff of the “Professorship Polymer Materials” in the laboratories of the F. A. Finger Institute at the Bauhaus University Weimar. Following verification of the required parameters of the fresh and hardened concrete [1], the mix design was tested at the concrete plant “Betonwerk Kahla”. Since the manufacture of the PCC was a “first” also for “Betonwerk Kahla”, the polymer dispersion was dosed manually. A further adjustment of the mix design was necessary only for the superplasticizer used, as it was found to be incompatible with...