An Entirely New Mixing Technology

Maschinenfabrik Gustav Eirich GmbH & Co KG, established in 1863, has developed and built mixers since 1903 for now 150 segments of industry. The first ring trough mixer was built in 1903 – for fine-grained concrete. The planetary mixer was invented in 1906 – again for processing concrete. Today, Eirich looks back on more than 100 years of experience and has evolved into a worldwide technology leader in industrial mixing technology.

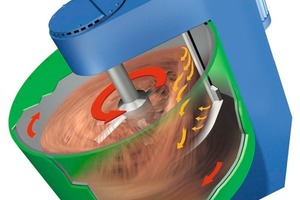

The first ring trough mixer was manufactured in 1903. But the system-inherent drawbacks of this mixer type were soon apparent: inadequate mix circulation on the inner orbit and excessive wear on the outer orbit. These findings motivated us to develop the mixer further until the first planetary mixer was built in 1906. But this generation of mixers, too, had improvement potential with regard to a homogeneous mix result and maintenance requirements. This led to the invention of the counterflow intensive mixer in 1924 (Fig. 1), followed, in 1960, by the first counterflow intensive mixer with agitator, designated type series “D” (Fig. 2). Mixers of this type built in the 70s are in operation in many concrete plants to this day.

True to the motto “better is the enemy of the good,” the Eirich mixers were continuously further developed and adjusted to the specific requirements of customers. This is how, in 1972, the first mixer with inclined rotating container and just one revolving tool with capacities from 1 liter to 3000 liters came to be developed (Fig. 3). The mixer with inclined mixing container, designated type “R,” brings significant advantages to concrete preparation. This is of particular interest in the production of high-quality concretes, e.g., facing concrete and roof tile concrete as well as the fast growing areas of SCC and UHPC. In other words: high-quality concretes for which a complete activation and homogenous distribution of cement and/or pigments are of critical importance for high product quality. What now is the difference between the Eirich mixing technology and conventional mixing systems?

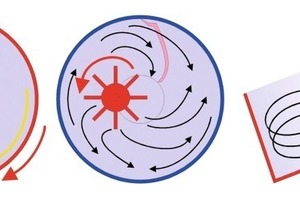

In a conventional mixer, the tool must transport the mix and simultaneously mix the constituents. In the Eirich mixer, the rotating container transports the mix and the tool must only mix it. This division of tasks has decisive advantages for existing and future concrete products and mix design developments. The separation of materials transport and the actual mixing task provides the degrees of freedom that permit the adjustment of the mixing process to the product. With an independently working mixing tool, the energy input required for the task at hand can be freely selected. In this way, the product must not be adjusted to the existing mixer. Since the mixing tool (agitator) must only mix and requires no contact to the mixer bottom, it can run at any desired speed. Tool speeds of between 1 m/s to 40 m/s are possible. A tool speed of between 3 m/s and 15 m/s has been found favorable for concrete mix production. Conventional mixing systems, for example, single- or twin-shaft mixers, or ring trough and planetary mixers, generally work at mixer tool speeds of approx. 1.5 m/s; twin-shaft mixers for fine-grained concretes are offered with speeds of up to 3 m/s.

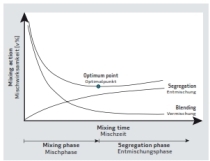

Eirich mixers feature, in addition to the agitator, a stationary tool combination that works as flow diverter and mixer bottom and wall wiper. The combination of a driven mixing pan, an independently working agitator and a stationary tool combination as flow diverter result in a 100% circulation of the materials during every revolution of the mixing pan (Fig. 4); this is what makes the Eirich mixing principle so effective. For concrete products manufacturers and precasters, the Eirich intensive mixer offers considerable savings potentials. Thanks to the adaptability of the mixing process to the product, mixing times can be partly cut short by 50%, error batches reduced and the expense on the materials side in this way lowered.

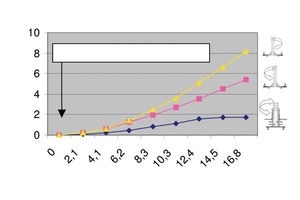

Figure 5 shows typical defects and the causes of error batches in paving block production. Why can most errors be avoided with the Eirich mixing technology? Let’s take the problem of the “breaking up of lumps” as an example. Sand, depending on the geographic location of the sand quarry, is interspersed with smaller or larger quantities of sand or clay lumps.

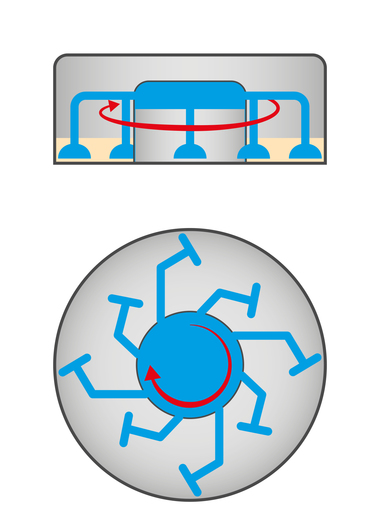

The cement, being a hydraulic binder, has a strong inclination to lump formation when the material in the processing chain from storage to placement in the mixer is at any position exposed to moisture, for example condensation water. The frequently processed finely ground cement, moreover, is especially susceptible to agglomeration. Clay and cement lumps are causes for quality problems: Not only in the form of superficial faults in the facing concrete of block pavers, but also in the form of voids in the concrete structure of precast components. Breaking up these lumps requires considerably more energy than can be generated in the mix by the conventional mixers with their constantly low tool speeds. The advantage of the intensive mixers is here is that, thanks to the separately working agitator, the tool speed and therefore the energy input into the mix can to a great extent be freely selected. The tool speeds of Eirich mixers is markedly higher than the speeds generated by conventional pan or trough mixers. Another quality criterion are voids caused by caking and lump formation in the mixer itself. Conventional mixers, inherent to their system, require numerous mixing paddles and tool holders inside the mixer (Fig. 7 and 8). These geometries offer the cement being placed in the mixer many surfaces for caking. This material accumulates in the course of day-to-day production until, through vibrations or under their own weight, it falls into the mix, where it remains on the surface and can no longer be intermixed or broken up. Here the intensive mixer has the advantage that mixers of up to 3 m³ capacity require only a single mixing tool and consequently offer a much smaller surface for caking (Fig. 9). In addition, the considerably faster tool speed generates very high centrifugal forces: any caking that occurs is thrown back into the mix where the lumps are once again broken up. Another factor for obtaining a uniformly good mix result (apart from the high energy output for breaking up lumps) is that the energy input is maintained at a constant level. However, the energy input can only be kept constant when friction and wear remain constant as well. If that is not the case, the electric energy applied by the drive of the tool will not be uniformly converted into the mixing process. Instead, an indefinable amount of energy is lost through friction and wear. The fast running agitator tool in the Eirich mixer needs no contact to the mixer bottom; friction and wear are low and remain largely constant. For conventional concrete mixers, the situation is different: the many tools that run along the mixer bottom or wall cause accordingly high friction and wear, and this is the reason why many ring trough and planetary mixers, as well as cone mixers, are frequently offered with ceramic lining (Fig. 7 and 8).

Eirich mixers do not need complex ceramic linings that are prone to break (Fig. 9).

Already the simple wear protection, based on steel, ensures that the mixer can be operated for many years without having to replace the linings of the mixer bottom or wall. For the agitator tools that are subjected to higher wear, patent-protected solutions of hard metal are available. This enables operating times of several years without exchanging the agitator. The installation of system-adapted moisture measuring systems is for Eirich a matter of course. The great variety of Eirich mixers ensures, firstly, the manufacture of products of high quality at a reproducibility unmatched by any other mixing system. And, secondly, it provides for future-proofness as it allows the production of concretes of any type by changing the mix parameters. The capacities of these mixers are generously designed. In one mixer, e.g., the mixer of type RV 12 (nominal filling level 400 liters), batch sizes from 0.3 m³ to 0.1 m³ fresh concrete of uniform quality can be processed. These are decisive advantages, in particular in the production of color mixes for multi-colored facing concretes.

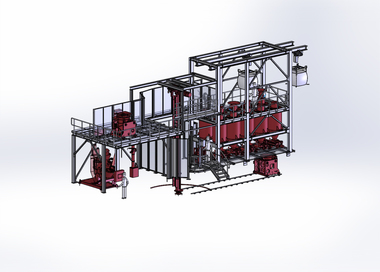

Thanks to the advantages of this mixing technology, the company is pleased to note that an increasing number of manufacturers of concrete products as well as precasters are interested in the Eirich mixing technology for their standard segments. In 2010, even mixers for ready-mixed concrete were sold, although Eirich does not court that particular market segment. Where future-proofness, savings in binding agents and admixtures, intermixing of all kinds of fibers, heating and cooling mixes are of interest, Eirich mixers are unrivaled. In the area of concrete products, a definite trend towards higher-quality mixing technology has taken place in Europe in the past two years. A great number of mixers have been replaced by Eirich mixers (Figs. 10, 11).

At the moment, several projects are underway involving the replacement of ring trough, planetary and cone mixers with Eirich mixers to enhance the quality and efficiency of concrete production. In conclusion, one of many examples for the versatility of Eirich mixing technology: In 2005 the Technical University of Munich published a report to the effect that in SCC production it is of advantage to work with a two-speed mixing process [1]: high speed during distribution of mixing water, low speed when the concrete is maturing. In this manner, SCC batch times of 3 minutes can be realized. This “hybrid” mixing process has in the meantime been adapted to UHPC production, likewise with batch times of 3 minutes. In addition to the short mixing time, a marked reduction of superplasticizers was noted. In addition Eirich intensive mixers are able to intermix fibers of all kind with ease – a task that regularly poses problems to most simple mixing systems. All those interested in the technology are offered the opportunity to run tests in Eirich’s engineering department in Hardheim. In addition, a visit to MFPA Leipzig is recommended, where an Eirich mixer is set up next to a ring trough and planetary mixer and where comparative tests (with subsequent investigations on the fresh and hardened concrete) are possible.