Low-noise Wacker-Neuson vibration tables in use at Gödde-Beton GmbH

Innovation and dynamics – these are the two core values GBL Gödde-Beton GmbH, based in Wadersloh, Westphalia, has adopted for its business. The precast plant‘s product range comprises structural precast components made of non-reinforced and reinforced concrete, custom-made items for gardening and landscaping, and products for civil engineering and building construction. The company specializes in producing fair-faced concrete elements. Several low-noise Wacker-Neuson vibration tables are being used successfully at the plant in order to meet the demanding requirements in terms of surface quality and appearance whilst also improving health and safety at the workplace and mitigating noise.

Optimal noise protection, top-class concrete compaction

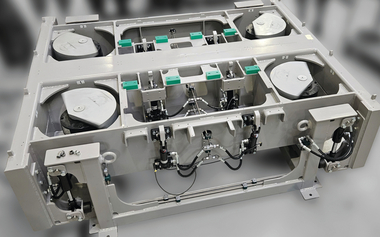

Reducing noise is becoming increasingly important at precast plants, especially with a view to workforce health. For example, vibration tables generate an enormously high amount of airborne noise due to their large surfaces, in particular during high-frequency vibration. GöddeBeton GmbH had also faced this problem - and resolved it together with Wacker Neuson concrete solutions. In a discussion with Gerd Stamm, Regional Product Specialist at Wacker Neuson concrete solutions, Managing Director Alfons Gödde explains what is really important to him: „We want to promote the protection of our employees and improve their working conditions – without having to compromise on excellent compaction quality.“ Wacker Neuson concrete solutions provided a 4 by 3 meter CS 36 low-noise vibration table to the precast producer for testing purposes. Employees were initially skeptical: „This table doesn‘t make any noise, so it probably can‘t compact the concrete properly,“ they first responded to the astonishingly low noise levels generated by the table. Then, their surprise was all the greater when they recognized its extraordinarily good compaction performance. The table was quickly incorporated in the production process to manufacture various items, and the company decided to purchase another three tables (one 3 m by 5 m table and two 4.5 m by 3 m tables).

Very good experience in everyday use

„We decided to purchase several smaller tables because they enable us to manufacture various elements simultaneously and render our business very flexible,“ explains Alfons Gödde. Today, the low-noise vibration tables are used for over 90% of all products manufactured at the plant. Each of the tables delivered by Wacker Neuson has a custom design. Both their dimensions and modes of vibration were adjusted to the needs of the customer. Some of the timber molds and formwork placed on the table vary greatly, which is why it is crucial to accurately adjust the vibration equipment to the mold or formwork system used in order to achieve perfect results.

Sophisticated technology ensures economical processes

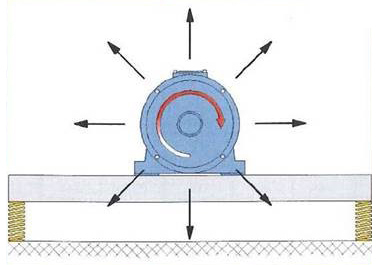

The CS 36 low-noise vibration table features Wacker Neuson external vibrators directly attached to the table underside, which guarantees a thorough, very uniform concrete compaction process. All components were incorporated in the concrete base, and the table top is vibration isolated by a foam layer extending over its entire size, which ensures that airborne noise generation is mitigated. In addition, the design of the CS 36 includes a dramatically reduced number of mechanical and electric parts compared to conventional vibration tables, which completely prevents the otherwise known, particularly loud rattling noises.

Apart from noise reduction and the uniformly high compaction performance, Alfons Gödde also mentions another important reason why he decided to buy the table: „An impressive feature of these tables is their excellent dimensional accuracy in the long term. The conventional tables we had used before showed deformation over time. Even though this deformation was only minor, such phenomena had serious implications for our products manufactured with a high degree of accuracy.“ The advantage of the CS 36 low-noise vibration table is that no deformation is possible because the steel plate fully rests on the concrete base.

Plug and play enables instant commissioning

Installation of the tables was extremely quick and easy: together with the first table, a Wacker Neuson FUE-M38 frequency inverter was delivered for power supply. This inverter had already been prepared for a wireless remote control unit, which was then fitted together with the other three tables. Gerd Stamm, Regional Product Specialist at Wacker Neuson concrete solutions, connected the tables to the grid in the factory and started them up. Since the junction boxes had already been installed and prepared, the tables only needed to be linked to the boxes by a plug-in connector. All four tables are now operated through a single frequency inverter and can be remote-controlled, which also ensures economical day-to-day operation and only short distances to be overcome by the operators. The remote control can be used to switch the tables on and off and to conveniently set the required vibration frequencies.

Tip: Make sure you get the investment grant (applies to Germany only)

The Steinbruchs-Berufsgenossenschaft, today known as BG RCI (Berufsgenossenschaft Rohstoffe und chemische Industrie; German statutory accident insurance organization for the raw materials and chemical industries) supports companies that take preventive measures to improve the working conditions of their employees by providing up to 20% of the investment amount, or up to 20,000 euros in a single bonus group (up to 50,000 euros per year per company). For more information on the „Those who do more get rewarded“ program, please visit www.stbg.de