Variable screw system:

PSF column shoe system

The introduction of the standards DIN 1055-4 wind loads and DIN 1045-1 reinforced concrete have increased the technical requirements in the field of structural engineering and the assembly of precast concrete columns during the last few years. In this regard, variable screw systems are an interesting alternative to conventional systems in precast concrete construction in order to realize the connections at the column shoe required in terms of statics.

Fields of application of the column shoe system

This kind of design transfers the assembly methods of fast and simple screw connections from the construction of steel halls to concrete construction. From the so far only partially fixed-ended columns with socket it is not far to the fully fixed-ended columns with an anchorage as used in steel construction. The Pfeifer column shoe system consisting of the PSF column shoe types and the PGS foundation anchors including the associated PGV connecting bolts allows a flexurally stiff connection between precast concrete column and foundation without the slightest effort. This system is completely structurally type approved in all sizes.

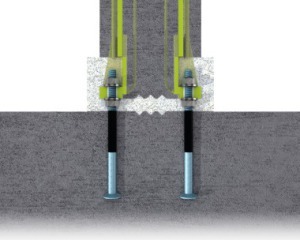

The advantages here are, in particular, the simple and fast assembly of the columns and the elimination of installation and assembly aids during installation. Using bolted connections, assembly is almost possible in all weathers. The immediate non-positive connection and the corresponding elimination of any supporting measures clearly simplify the installation process making it more efficient. The use of prefabricated screw connections in the column shoe furthermore enables to transfer additional mounting loads when assembling the girder and wall slabs already during construction.

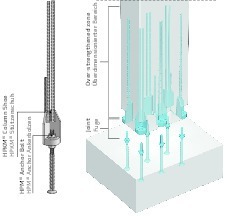

The column shoe system offers an additional advantage for the construction in existing context or for building expansions. In such a case the conventional construction methods, such as socket base and formed foundations, can hardly be applied owing to the dimensions of the components. A variable screw system offers the structural engineer the option to connect the building components planned with just a small edge distance to the existing building. In the event of difficult foundation measures it is also possible to sink the innovative PDK foundation anchor less deep into thin foundation plates.

Technical verifications

However, the aspect of a reliable building construction in compliance with building codes becomes more and more important. This means, in particular, that either a structurally type-approved calculation verification has to be provided or a national technical approval – if there is no standard concerning the calculation. The latter is often required if special steel grades are used or for anchorages with anchor heads according to the theory of fastening technology. All approved building components have to be marked with an Ü-sign, which classifies them as being manufactured in a controlled process. Here it is of course out of question to use low-grade steels and unapproved welders not complying with the national regulations and surveillance. The Ü-sign shows that the requirements of the approval were taken into consideration in the manufacturing process in the factory and that there is a factory production control system, which in turn is externally monitored by an accredited body on a regular basis. Briefly, it is a certificate of conformity which substantiates the correctly used materials and the proper production process in accordance with the approval.

However, even type-approved building components have to be manufactured with appropriate attention. Here an external quality control is not mandatory, but possible. It is essential that there are building codes applicable to all materials used. This might, however, limit the range of suppliers. Buying cheap reinforcement steel without approval is therefore out of question anyhow.

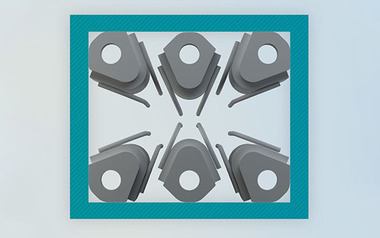

Using the structurally type-approved column shoe system consisting of the column shoe and a foundation anchor including the associated connecting bolts or as a threaded anchor element enable performing a flexurally stiff connection between precast concrete columns and foundations without the slightest effort. Connections from columns to bars or girders can be performed in a similar way.

For this purpose, there are various column shoes available with firmly welded reinforcement steel anchors or even with bars that can be screwed in. An advantage of the latter ones is the possibility to adapt the lengths right in the last second owing to modified connection conditions of the reinforcing steel of the precast concrete column. Therefore, longer or shorted bars are simply screwed in the threaded base plate.

The use of industrial column shoe systems provides the building owner and the planning engineer a variety of possibilities for the application in precast construction. Variable screw systems, in particular, help to optimize installation and construction processes. In case of complex industrial facilities and difficult foundation measures this can account for a significant economic benefit in total.

PFEIFER Seil- und Hebetechnik GmbH

Dr.-Karl-Lenz-Straße 66

87700 Memmingen

+49 8331 937-290

bautechnik@pfeifer.de

www.pfeifer.de