Concrete modules for solar park

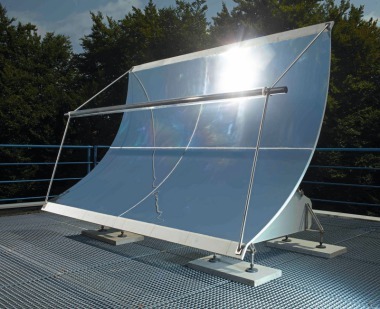

Solar power has a future in Germany. Now that Germany is abandoning nuclear energy, ecologically generated power will increasingly move into the foreground during the next decades. Apart from wind parks, more and more solar fields are being created in suitable locations. Where greater energy benefits are produced, large areas are required for setting up the solar panels. Apart from roof surfaces, former industrial sites are also effective: e.g., in the Lower Saxonian Sassenburg Triangle. Here, one of the largest solar parks of Lower Saxonia has been set up. The foundations for the panels were supplied by the German concrete block specialist F.C. Nüdling in Fulda.

Old field with new uses

The old industrial site in Sassenburg has lain fallow for several years. When the old hall was dismantled it was found that foundations on its lower level would make the erection of new structures difficult. Their removal would have cost a great deal of time and money. For that reason, no new utilization concept was found for the spacious site. In 2009, a new utilization opportunity offered itself when an investor was looking for land for the erection of a solar park. The owner of the property contacted the potential investor and finally found in the company Wirsol in Waghäusel the right partner. On a total area of 25,000 m² one of the largest solar parks in Lower Saxonia was now created. The 7,600 solar modules were erected on a total of 3,800 special support elements that the company F.C. Nüdling Betonelemente GmbH + Co. KG supplied and set up in the field. In preparation for their installation, the ground was leveled and the soil conditioned with 10,000 tons of a mineral mix placed in the areas where the solar modules would be set up. The resulting strip foundations offer sufficient stability for the concrete modules. Approx. 15,000 tons of top soil were processed in the spaces between the rows for subsequent greening.

Solar modules facilitate erection

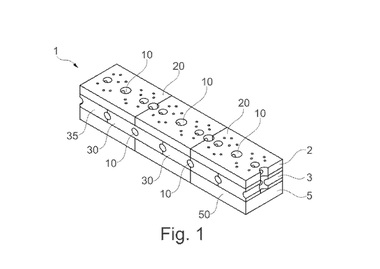

The support element for the solar modules was developed by F.C. Nüdling Betonelemente in collaboration with the EDAG Group. It is specifically suited for already paved fields, e.g., former military and industrial sites. The former industrial site in Sassenburg was ideal for this purpose. The elements can be transported to the site and installed where required. In Sassenburg, an excavator fitted with special transport equipment was used for positioning the modules. Always two modules are accommodated on one support element made of concrete, which are mounted on rails. The erection of complex support structures of steel or aluminum was not possible in Sassenburg. Additional foundation works were also not required due to the support elements’ own weight of approx. 480 kg. The use of the precast concrete units considerably reduced the erection time. The concrete units were installed in such a way that the inclination on the upper side points towards the south. The solar panels are fixed to the rails with two center clamps and four end clamps. The rails, in turn, were fixed to the supporting block with only four screws. All erection works on the panels could be carried out at an ergonomically favorable height of maximum 95 cm. The special H shape of the concrete supports moreover is perfectly suited to accommodate the lead-throughs for the cables safely and space-saving.

In October 2011, following installation of the inverter and the transfer station, the solar power station could go on stream. At a nominal rating of 1.8 megawatt (MWp), it now supplies 400 households with CO2 neutral power. The solar modules from F.C. Nüdling have contributed to the completion of the construction project within the shortest possible time.