Cooperation:

Organic Solar Panels in

Concrete Building Façades

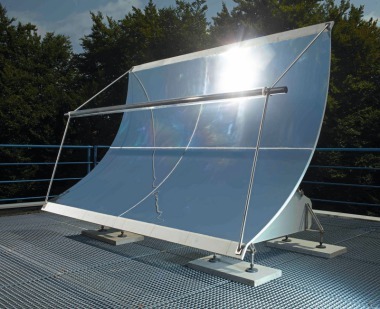

Heliatek GmbH, a global leader in high-end solar PV technology, has signed a joint development agreement with Reckli GmbH, a world leader in the manufacture of elastic molds for concrete building façades. This will enable vertical concrete walls of buildings to become highly efficient solar energy harvesters by integrating Heliatek’s organic solar panels onto concrete façade blocks. This new Building Integrated Photovoltaic solution (BIPV solution) will combine energy harvesting to reduce a building’s carbon footprint with a discrete, aesthetically pleasing, visual appearance.

Heliatek’s award winning organic photovoltaic (OPV) technology is ideally suited to this application, because it is ultra-light, ultra-thin, and ultra-powerful, as it harvests the sun’s energy at peak efficiency across a wide range of real world conditions for more of the time than traditional solar technologies. One major problem with conventional solar panels is that their efficiency drops off with every degree in temperature gained. Heliatek’s solar technology, in contrast, is unique in that the efficiency of its organic photovoltaic modules remains constant up to 80 °C. This is also the reason why Heliatek’s panels can be integrated onto the concrete without any need for ventilation.

Superior low light performance

Similarly, if the light intensity decreases, the efficiency of conventional solar panels decreases as well. Heliatek’s panels are consistently efficient from full sun down to a tenth of full sun, such as on a cloudy day or when not directly facing the sun, only receiving indirect light. Heliatek estimates that, under real world conditions, the combination of these two factors – temperature independence and superior low light performance – will increase the specific annual harvesting yield of its panels by 10-20 % compared to conventional solar panels, depending on the location and orientation of the PV façade system.

Thibaud Le Séguillon, CEO of Heliatek, explained, “Today, vertical walls are rarely used for solar energy gathering, despite the fact that the vertical building walls offer a much larger installation area than roof tops. By integrating our ultra-light, ultra-thin solar panels directly onto the blocks of the concrete façade, the installation costs will be reduced along with the visual impact as the panels become a discrete part of the façade.”

Truly green

Dr. Bernd Trompeter, Managing Director of Reckli, added, “By 2020, an EU directive will require new buildings to be nearly zero-energy as part of the drive to be green and so, having every wall being an active producer of solar electricity will be a major contributor to achieving truly green buildings.”

According to Trompeter Reckli chose Heliatek as being key in the company’s drive to low carbon, environmentally friendly products for two reasons: First, the management of Reckli is impressed by the effectiveness of the state-of-the-art, organic solar technology. Second, this solar technology has a truly green, zero environmental impact thanks to no toxic ingredients, non-toxic manufacturing with very little energy and material consumption, and ease of disposal as the modules are 99% PET plastic. “These factors make Heliatek the first, completely green, solar technology, which is why we are incorporating it into our portfolio. This new BIOPV application will serve as a strong lever to start a new, truly green revolution in building design” said Trompeter.

Variety of colors, cost competitive

Architecturally, the new Heliatek and Reckli solar concrete façade will offer several advantages. The solar cells are deposited in a roll-to-roll deposition process on a thin, flexible, lightweight plastic sheet so that there are no safety issues unlike with glass modules, which require very secure handling and installation. At only 0.5 kilograms per square meter, compared to conventional panels at 10 to 15 kilograms per square meter, structural support issues are minimized. The BIPV modules can be added to a building’s façade in non-intrusive ways and will be available in a variety of colors and dimensions.

According to the cooperation partners the new BIOPV application will be highly cost competitive due to mass production within a few years when the new solar façade modules will be available.