Holcim manufactures ultra-high performance concrete panels with Kuralon fibre reinforcement

For its Ductal Cladding and Ductal Envelope concrete panel solutions, building materials giant Holcim uses reinforcement with fibres made from polyvinyl alcohol resin (PVA). More specifically, Holcim uses Kuralon fibres from the specialty chemicals company Kuraray for reinforcement.

Building progress for people and the planet

Holcim AG, headquartered in Zug, Switzerland, is one of the largest producers of building materials in the world. After the merger with Lafarge in 2016, the Group was temporarily called LafargeHolcim, but has been known as Holcim again since 2021. The world‘s leading provider of innovative and sustainable building solutions had net sales of CHF 27 billion in 2023. Driven by the purpose to build progress for people and the planet, Holcim‘s more than 63,000 employees are on a mission to decarbonize construction, while improving living standards for all. Holcim empowers its customers across all regions to build better with less, with a broad range of low-carbon and circular solutions – from EcoPact and EcoPlanet to the circular technology platform EcoCycle. Through innovative systems, from Elevate roofing to PRB insulation, Holcim makes buildings more sustainable in use, driving energy efficiency and green retrofitting. With sustainability at the core of the strategy, Holcim is on the way to becoming a net-zero company with 1.5°C targets validated by SBTi. Holcim is the company behind some of the world‘s most trusted brands in the construction sector, including Aggregate Industries, Disensa, Duro-Last, Elevate, Geocycle, Holcim, Lafarge, Malarkey Roofing Products, and PRB.

The ultra-high performance fibre concrete from Holcim: Ductal

For more than 25 years, Holcim has been producing the most advanced technologies and services in the field of ultra-high performance concrete (UHPC). Ductal – born out of a desire to minimise cost and maximise performance – stands for optimum strength, ductility, and durability. Thanks to decades of global practice, research, and development, Holcim has the technology and expertise to realise even the most ambitious projects, anywhere in the world. Ductal is now available in different variants to meet specific requirements. When Ductal is used for load-bearing applications, steel fibres are usually used as reinforcement. For architectural applications with special aesthetic requirements – such as non-load-bearing façade panels or street furniture – Holcim uses fibres made of polyvinyl alcohol resin: Kuralon fibres from Kuraray. Their advantages include the fact that they are not brittle, remain invisible in a white concrete product with their yellowish-white colour and cannot rust, as steel fibres do.

A success story spanning decades

The French concrete manufacturer Lafarge, which has since merged with Holcim, discovered Kuralon back in the late 1990s. At that time, Lafarge had developed the new Ductal as UHPC concrete – originally with steel fibres as reinforcement. In some applications, however, prolonged exposure to water led to corrosion of the steel components. In aesthetically demanding application scenarios such as façade cladding, steel reinforcement was therefore not an option. However, with Kuralon, the PVA fibres from Kuraray, an excellent reinforcement alternative was soon found.

International specialty chemicals company with a large European presence

Kuraray is headquartered in Tokyo. The publicly listed Kuraray Group employs more than 11,700 people worldwide and has a turnover of 5.5 billion euros. The globally active specialty chemicals company is one of the largest suppliers of polymers and synthetic microfibres for many industries, including Kuraray Poval, Mowital, Trosifol, and Clearfil. The wholly owned subsidiary Kuraray Europe GmbH is headquartered in Hattersheim near Frankfurt am Main. In addition to the more than 830 employees at several sites in Germany, there are a further 215 employees at seven European sites, who are also involved in the development and application of innovative high-performance materials for numerous industries. Customers include the automotive, paper, glass, and packaging industries as well as architects and dentists.

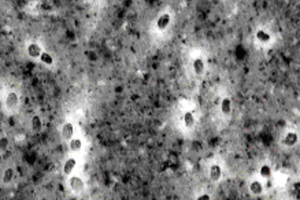

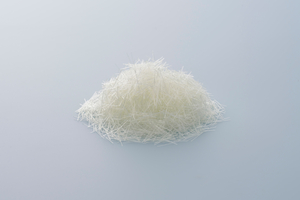

Synthetic reinforcing fibre made from polyvinyl alcohol

At the end of the 1990s, the Ductal managers came across Kuralon as an alternative for the reinforcement of their ultra-high-performance fibre-reinforced concrete. Kuralon is a synthetic fibre that Kuraray produces from polyvinyl alcohol resin (PVA). Kuraray began the commercial production of PVA in 1950, and the fibre has also been used in cement composites for a long time. It was originally used as a substitute for asbestos. Kuralon has long since proven its worth in the production of fibre-reinforced concrete. Compared to other fibre materials such as steel, alkali-resistant (AR) glass and polypropylene, Kuraray‘s PVA fibres have special properties.

Kuralon fibres have a number of advantages when it comes to concrete reinforcement:

High strength,

High modulus,

Low elongation,

Good adhesion to the cement matrix,

Alkali resistance,

UV resistance,

Low weight,

No corrosion.

The advantages of reinforcement with PVA fibres

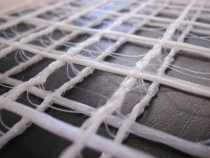

In the particular Ductal application scenario – concrete cladding with aesthetic requirements – other reinforcement variants could also be considered in principle, but they all have specific disadvantages: from the low-strength polypropylene fibre to the alkali-resistant glass fibre (Glassfibre Reinforced Concrete, GRC), which is more difficult to process and less durable. Simon Herbé, Ductal Worldwide Development Engineer at Holcim, explains: „The great advantage of Kuralon is that the PVA fibres are simply co moulded into the required moulds. Ductal with Kuralon is self-levelling. This speeds up the application immensely.“ While the PVA fibres, which form the reinforcement for Ductal, are simply poured together with the cement, this is different with glass fibre reinforced concrete (GRC). Here, the glass fibres are sprayed on afterwards, as they are thixotropic and therefore change their viscosity depending on the load.

Longer service life with PVA fibres

However, GRC is not only more complicated to work with, but also has a number of other disadvantages compared to self-levelling Ductal with Kuralon. This is due to the fact that the performance of such AR or GRC concrete suffers over the years as the alkaline cement matrix causes the fibres to become brittle. As Simon Herbé from Holcim explains: „This is not the case with the Kuralon mix in Ductal. After five or even ten years, no change can be detected there. So Ductal has an exceptionally long service life.“ Even with the usual standard testing in hot water, the glass fibre reinforced concrete also encounters problems – in contrast to Ductal with Kuralon. „Last but not least, Ductal also shows superior behaviour under compressive loading,“ Herbé points out. „Glass fibre reinforced concrete can crack under compressive loading, while Ductal has much better ductility thanks to the PVA fibres.“

Ductal cladding: industrially manufactured, infinitely mouldable

Holcim now offers Ductal façade elements in two variants: Ductal Cladding and Ductal Envelope. Ductal Cladding are cladding panels made of ultra-high performance fibre concrete that combine the best aspects of industrially manufactured concrete elements with the versatility of a material that can be shaped indefinitely. The thin, lightweight, and large-format Ductal panels can be installed horizontally or vertically, covering entire storey heights of up to four metres, and can also be supplemented with individual geometries and one-piece corner elements on request. The exceptional mechanical properties of the material reduce installation time and the number of fixing points, which in turn lowers project costs.

Ductal Envelope: creative shapes and textures with high durability

Ductal Envelope offers customers even more design freedom and can bring architectural ideas to life – with high-performance façade, roof, and envelope systems. They can be bent like main or secondary skins, adapting to the most complex shapes and aesthetic requirements while offering durable, high-impact resistance. Ductal Envelope enables decorative and protective façade elements, latticework, perforated façades, and urban furniture, making innovation a reality in a variety of textures, finishes, and colours. Ductal can be moulded into organic shapes or cut into clean angles. Its mineral nature allows it to add depth and shadow – or simply blend in.

The largest project to date: Lusail Plaza in Qatar

The superior properties of Ductal soon led to market success. Over the past 15 years, more and more construction projects have been realised with the innovative UHPC prefabricated façade and roof elements with Kuralon fibres. A recent example of the use of a Kuralon-reinforced Ductal cladding is a major project in Qatar: Lusail Plaza. Around four office towers with a glass and aluminium façade, the Lusail Plaza Towers, a completely new quarter with multi-storey buildings, has been created in Lusail, all of which have been fitted with façade and roof panels made of Ductal. With a total material usage of 16,000 tonnes, this is the largest project ever realised with the Ductal Envelope solution. This is where Ductal Envelope shows its full strength. The individual panels are designed entirely in line with the architectural vision of this project, which was created by architects Foster + Partners: light, strong, and aesthetic.

Greater sustainability

With the addition of Kuralon, Holcim can produce its Ductal Cladding and Ductal Envelope solutions particularly thinly. This reduces concrete consumption: the thin Ductal solutions give construction projects a better carbon footprint. At the same time, the thinner and lighter panels also reduce labour and transport costs during the construction phase. Ductal with Kuralon therefore not only has aesthetic advantages, but also increases sustainability. Ductal thus fulfils the Holcim motto: „Building better with less.“

Thinner, more aesthetic façade elements

„In most cases, architects, and builders take advantage of the high strength of Ductal to design the panels cast with it to be particularly thin,“ says Simon Herbé from Holcim. „The good adhesion of Kuralon with the cement matrix is an important advantage – it gives our Ductal Cladding and Ductal Envelope solutions their superior mechanical properties.“ But aesthetic considerations are often just as important when choosing Holcim‘s UHPC panels. „Kuralon simply has a good white-yellow colour that makes the fibres invisible on the surface,“ explains Herbé. „Moreover, they flow easily in complex shapes, which are sometimes even perforated. You could say that with Ductal Cladding and especially with Ductal Envelope, we unleash the imagination of architects.“

Joint innovation, also in the future

Kuraray‘s Kuralon fibres have always played an important role in the success of Ductal Cladding and Ductal Envelope. Nevertheless, development continues. „We appreciate that Kuraray continues to work on developing new variants of its PVA fibres with even more favourable properties,“ says Herbé. Through its close cooperation with Kuraray, Holcim aims to keep improving its Ductal solutions. „The fact that Kuraray is always willing to work with us to drive innovation means a lot to us,“ concludes Simon Herbé.

CONTACT

Holcim (Deutschland) GmbH

Troplowitzstraße 5

22529 Hamburg/Germany

+49 40 36002-0