DTM focuses on safety walls from Nordbeton

Following its successful debut in 2011, the German Touring Car Championship followed up by staging a special event in the summer of 2012. On 14 and 15 July, in addition to the qualifying runs, an exclusive show event was held for the fans, without championship ranking. After the entire inner oval of the Munich Olympic Stadium had been covered, filled in and asphalted, a racecourse modeled on an oversized go-kart track was erected, with safeguarding by around 1,500 m of precast concrete safety wall elements.

The race was held as a “duel” on two synchronously mirrored racetracks of equal length. The race took place with the original racecars of the current German Touring Car Championship.

Special requirements

The precast concrete safety walls were purpose-made for this event to the specifications of the DTM and the German Motor Sports Association (DMSB). The contract for their manufacture was awarded to Nordbeton GmbH, located in Friesoythe in Lower Saxony, Germany – a company that has manufactured concrete safety walls for public roads for 15 years.

“This special production lot, and particularly its transport, was cost-efficiently realized for both parties through the efforts of our subsidiary in Lower Franconia,” says Steffen Plötner, Managing Director of Nordbeton GmbH. The fact that the DTM was planned from the very beginning for a minimum of three events (2011/2012/2013) made it possible for Nordbeton to gain a foothold in the event and motor sports sector.

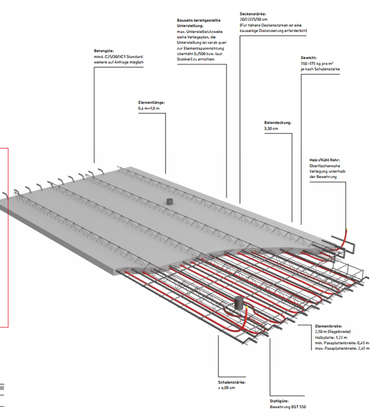

The individual elements were manufactured “overhead” with concrete of strength class C 30/37. The basis for the design and/or the reinforcement, according to Plötner, was the H2 standard product from Nordbeton from its Public Road Traffic Segment. The geometry and the weight of the individual components were adapted to the requirements of the German Motor Sports Association. Interestingly enough, comments Plötner, the requirements for the racing sports elements are in some respects the exact opposite of the requirements placed on precast concrete safety walls used in public road traffic. Admittedly, racecars in fact have little in common with series-production passenger cars.

Ideal for city racetracks

Through the close and intensive collaboration with DTM as well as systematic implementation of the requirements of DMSB for motor sports, a system was designed that can be realized for nearly all imaginable courses and curves. During erection, the individual elements, some of which weigh up to three tons, are force-locked to create a chain of great tensile strength. If worse comes to worst, the wall prevents the racing cars from crashing through and protects drivers and spectators. Connection of the elements to the ground – for example, by anchorage in the asphalt – is not required. Because the road surface is not damaged during erection, the system is suitable for use as boundaries for municipal race courses on suitably blocked public roads or on large parking lots.

High degree of safety

The high efficiency of the system was already demonstrated at the debut event last year. Some of the vehicles had violent encounters with the concrete wall during practice and during the race. As expected, the only damage that occurred was to the cars. Drivers or spectators were not injured. The only change to the walls was that the concrete elements were shifted by a few centimeters upon impact and could be realigned during a break in the race.

In the meantime, Nordbeton GmbH has successfully completed additional jobs in the event and motor sports sector. In December of last year, for example, the Race of Champions 2011 in the Düsseldorfer Esprit Arena was protected by a precast concrete safety wall made by Nordbeton GmbH.