A new building system: UHPC with vacuum insulation

Ultra-strength, highly insulating and slender – these are the adjectives Vertriebsgesell-schaft BauKom uses to describe new structural elements made of UHPC, the ultra high performance concrete, with integrated vacuum insulation. The elements for façade, floor and roof of the building system developed by them, that is, the so-called ZeroEnergy Building System, are to be manufactured at the factory according to individual specifications with millimeter precision. According to the designers, using the so-called ZeroEnergy vacuum insulating panels means to gain space: The effective floor area of the building made of ZeroEnergy elements is 30% larger compared to a conventional building, for the same gross floor area. And using ZeroEnergy vacuum insulating panels, furthermore, reduces the construction costs by approx. 40% compared to conventional construction methods in compliance with the German Energy Savings Ordinance (EnEV), as stated by the designers.

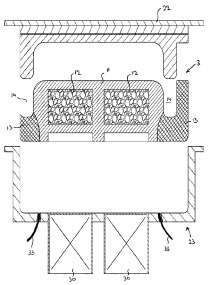

Tried and tested machines that are well-known in wood manufacturing and are converted for the particular requirements of UHPC are used for the production of ZeroEnergy structural elements. In the first step, the molds are cast with UHPC in a vacuum press (element sizes up to 30 x 3.3 m) and single panels (honeycomb elements) are made of UHPC. The liquid UHPC is placed in several layers, being then grouted in a vacuum press. This ensures the complete filling of the mold and very smooth surfaces. Any surface textures requested and almost any color is possible. Up to 30 honeycomb elements can be cast and grout at the same time. Afterwards, the UHPC panels mature at 90 °C and 90% air humidity for about 70 hours. This is followed by a drying period at 90 °C and a 90% vacuum. The entire free water contained in the UHPC evaporates completely.

Cutting with millimeter precision

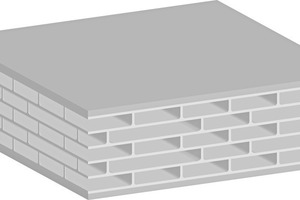

Subsequently, a thin aluminum coating of approx. 20 microns is sprayed to the inner surface of the dried panel. The elements become permanently vacuum-tight due to the coating. The individual honeycomb elements are coated with adhesive and are stacked on top of each other in a vacuum press. Spreaders are placed between the individual layers in order to prevent an immediate bond of the individual layers. The opening of the vacuum press is closed airtight by a vacuum blanket, evacuating the air. The spreaders are removed. Due to the dead weight, the panels close up and adhere to each other. The cavities in the panels are under vacuum. The aluminum that has been applied previously prevents air from ingressing into the cavities. The vacuum blanket is removed, letting air into the press. The air pressure – 1 bar or about 10 tons/m2 – now bearing against the panels provides for permanent bonding of the panels.

According to BIM specifications, a CNC waterjet cutting machine cuts the vacuum insulating panels to wall and floor sizes including window and door block-outs, with millimeter precision. Then, the edge banding of the UHPC is glued in and the finishing process of the element starts on a portal-type machine that is especially adapted. All edges are profiled and the service ducts for the building services are milled accurately to the millimeter.

In the next step, windows and doors are installed at the factory, as well as other electrical installations. The element is ready for assembly at the construction site. As an option, façade claddings such as bricks, natural stone or glass are applied to the UHPC panel at the factory using tilting assembly tables; they are later fastened to the UHPC wall panel on site. After several decades, the façade cladding can easily be replaced by another one.

For new construction and refurbishment

The thickness of the ZeroEnergy structural elements varies according to requirements of the building statics. The façade element of a single-family house has a thickness of 120 mm, plus the requested interior and exterior lining, featuring a U-value of 0.04 W/m²K and a weight of just about 150 kg/m² in case of clinker brick lining. Therefore, pile foundations made of UHPC are appropriate for the foundation by means of a high-strength ground slab with very good insulating properties, again reducing the overall costs and the construction time significantly. According to the designers, the vacuum façade elements are also a convincing alternative when it comes to the refurbishment of façades. The wide range of colors and possibilities for design would meet the requests of architects, clients and public authorities perfectly, as reported. For the façade renewal, the ZeroEnergy wall panels are adjusted to the existing façade accurately to the millimeter with the aid of 3D cloud laser scanning and are prefabricated at the factory accordingly.