A not-everyday pallet circuit installed

in Austria

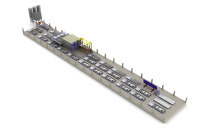

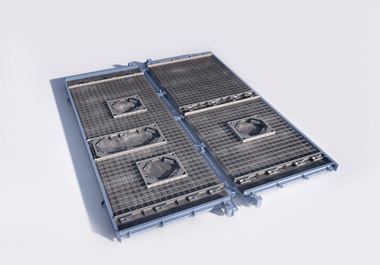

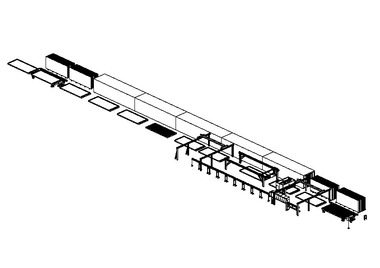

Spatial constraints prompted the companies Mörzinger Bau and Kinast Maschinensysteme to decide on a vertical instead of horizontal pallet circuit concept when ordering a new production plant.

Walter Mörzinger, Managing Director of Mörzinger Bau GmbH, and Gerd Kinast, Managing Director and owner of Kinast Maschinensysteme GmbH, met for the first time in November 2012 to talk about a new pallet circuit for production of double walls and floor elements. Before that Mörzinger had looked at various plants of other major manufacturers.

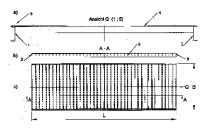

The Managing Director’s wish, to process different pallet widths of 2.2 x 10.6 m and 3.05 x 10.6 m on a single pallet circuit seemed impossible to realize. The existing hall with a floor plan of 13.7 x 70 m further limited the possibilities. For this...