Innovation: Battery-mold circulation system

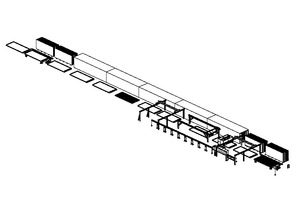

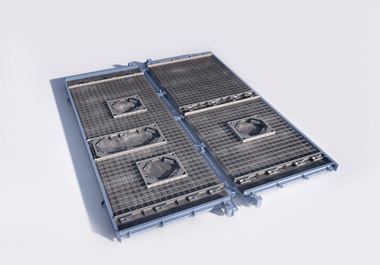

Battery molds, among others, provide solid walls which feature smooth surfaces as far as the main exposed sides are concerned, however their output is often limited owing to the closed design. The innovative battery-mold circulation system, according to the manufacturer, allows manufacturing precast concrete elements with smooth surfaces on both sides with the productivity of a circulation system. It combines existing techniques with the circulation mode where wall modules are cast in vertical position. The innovative system has all advantages of a vertical production process, but none of the disadvantages, such as high expenditure in the preparation process, high utilization of a crane and the limited output. The newly developed manufacturing system comes with two production lines integrated in the circulation. A horizontal line serving the preparation and a vertical line serving the pouring and hardening process of concrete. The production starts with a horizontal pallet which is cleaned, furnished with formwork, applied with release agent on both sides, prepared with reinforcement and provided with embedded parts by means of existing technology, similar to a conventional circulation system. These work steps are carried out in a horizontal position in short cycle times.

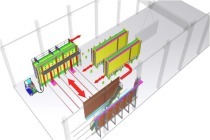

The passage through the heated curing tunnel can be of any length

At the end of the production line, the prepared pallets are put in an upright position, transferred into a vertical magazine, and then bundled and clamped into packages of an appropriate number. The packages tied up accordingly are carried to the next station in a flow process and there the casting compartments of the clamped packages are filled with concrete completely. Afterwards the package is passing through a heated curing tunnel where the concrete is heat-treated for faster hardening. After passing the heated curing tunnel, the package in unclamped and the pallets are transferred again to the horizontal production line using a tilting station. After the removal of the precast element, the pallet is ready for next circulation. The advantage of this system lies in the combination of the horizontal preparation and the vertical production process. Moreover, there is the possibility to have the clamped packages pass a heated curing tunnel of any length. In this way, the output of smooth walls on both sides is scalable and the cycle time can be kept short.

CONTACT

B.T. innovation GmbH

Sudenburger Wuhne 60

39116 Magdeburg/Germany

+ 49 391 73520