A premium package – textile-covered reinforced-concrete pipes for wastewater disposal

Pipelines are used for the cost-effective transport of a wide range of media. To ensure their continued operational reliability, they must not only be tight and exhibit a high hydraulic or pneumatic performance but also be capable of withstanding loads without damage.

Excavators are normally used for civil works and also for the pipeline installation process itself. Special lifting equipment is necessary to handle diameters larger than DN 2000 owing to the heavy pipe segments, which makes the installation of large pipes very costly.

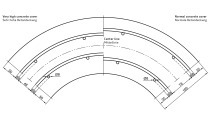

In the field of wastewater disposal, reinforced-concrete pipes with two steel reinforcement cages are used for diameters larger than DN 1300. Unlike such conventional reinforced-concrete pipes, composite textile-covered concrete pipes are characterized by the fact that the textile cover protects the pipe from any external factors that may cause damage whilst enabling a reduction in wall thickness – and thus weight – as a result of eliminating the need for the external concrete cover. This reduction in weight not only optimizes transport and installation; it also ensures greater mechanical resistance and lowers total construction cost [1].

As part of a research project funded by the Federal Ministry for Economic Affairs and Energy, cooperation partners Mattes & Ammann GmbH & Co. KG (textile cover), the Institute of Textile Technology and Process Engineering, Denkendorf (manufacturing technologies for the textile cover), Betonwerk Steinbach GmbH & Co. KG (manufacturing and installation technologies for composite textile-covered concrete pipes) and IAB Weimar gGmbH (overall technology and material concept for composite textile-covered concrete pipes) are developing a method for producing large textile-covered concrete pipes for the buried installation of wastewater sewer systems [1].

Its practical implementation is based on using a prefabricated textile structure that replaces the external steel reinforcement. In the preferred technological concept, this textile structure is designed as a stabilized tube that is integrated into the production mold, similar to inserting reinforcing steel cages during conventional pipe production.

The transverse textile reinforcement is composed of double-faced circular knitted fabrics with reinforcing filaments smoothly incorporated in the circumferential direction. Textile fabrics including glass or carbon fibers provide sufficiently high strength parameters, and they are relatively easy to produce. Strength tests carried out with textile-covered concrete cylinders proved their effective incorporation into the concrete matrix by exhibiting differentiated bursting behavior, depending on the type of fiber used. The research also includes the evaluation of options for the specific prestressing of the textile cover as part of the manufacturing process or during concrete placement ...

You can read the complete text in the yearbook Beton Bauteile 2017 (see right side)