Adaptions of cement portfolio concluded

Since the beginning of 2016, Opterra Wössingen GmbH has been offering CEM II/A-M (V-LL 52.5 in exchange of CEM II/B-M (V-LL) 42.5 R-AZ due to growing requirements.

Continuous further developments in close coordination to the requirements prevailing in the market lead to the adaptions of the cement portfolio. There is a growing demand for higher strengths. For this reason, the CEM II/A-M (V-LL) 52.5 N replaces the CEM II/B-M (V-LL) 42.2 R-AZ, which has been used for such applications so far.

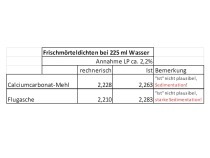

Higher strengths can be achieved by optimizing the main constituents fly ash (V) and limestone powder (LL) without increasing the water requirement. This leads to the fact that the CEM II/A-M (V-LL) 52.5 N has a normal initial strength and achieves an even higher strength after hardening than the CEM II/B-M (V-LL) 42.2 R-AZ offered so far. The field of application for the new Portland composite cement of Opterra Wössingen GmbH includes ready-mixed concretes - in particular, during the cold season –, ready-mixed concretes with higher strength requirements as well as concrete products and precast concrete components.

Optastone with optimized particle size distribution

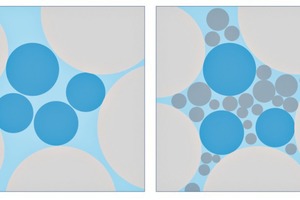

Following the successful introduction of the Optastone special cement manufactured at the Karsdorf factory for concrete paving stones and concrete products, Optastone has been manufactured at the Opterra factory in Wössingen since February. The special grinding of Optastone as well as the use of blast-furnace slag as main constituent, apart from Portland cement clinker, provide for the fact that the concrete produced with this special cement has a very good compacting property and an excellent surface quality. Optastone meets the requirements of Portland slag cement CEM II/A-S 42.5 R in accordance with DIN EN 197‑1. As bright cement, the product supports a homogenous and intensive coloring regarding the use of color pigments. In addition, the risk of discolorations, so-called efflorescence, on the concrete surface is reduced significantly. Optastone features an optimum particle size distribution. This enables an even better compaction and more uniform surface texture.

Optastone is particularly suitable for the production of concrete pavers and concrete products made of earth-moist concrete.