Master X-Seed STE 35: Strength-enhancing admixture for sustainable hollow core slabs production

Reducing the CEM I dosage or replacing it with clinker-reduced cement types or SCMs can improve the sustainability of hollow core slabs, but can lead to performance losses in terms of strength development at early and late ages. Master X-Seed STE 35 supports sustainable construction by optimizing the concrete mix.

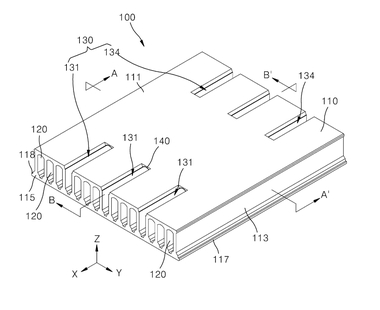

The production of prestressed hollow core slabs takes place in the plant on long tracks (120-150 m) on which prestressing cables are laid out, suitably distributed, and stretched. Concrete casting is carried out continuously with the use of special machines (mainly extruders and slipformers). The two types of machines differ by their mode of operation and therefore by the forces imposed on the concrete. Because of the different compaction processes of extruders and slipformers, the mix design used to produce the hollow core slabs can vary significantly.

In the case of production with extruders, the mix usually contains a lower amount of cement per m3 of concrete (in the range of 300-360 kg/m3) and a lower water-to-cement ratio. While using slipformer instead, the mix is commonly based on a higher cement dosage (in the range of 380-450 kg/m3) and a higher water-to-cement ratio. In both cases, the need to cut the slabs usually after around 16 hours to meet the required production output forces the hollow core slabs producers to use CEM I 52.5 R in their concrete recipes. CEM I is composed of a clinker content ≥ 95%. As clinker is the main contributor of CO2 emissions in concrete, this negatively impacts the embodied carbon of the elements. Despite the very limited volume per m3 of clinker in concrete, which is usually around 10-15%, it accounts for more than 90% of CO2 emissions associated with concrete mixes. Lowering the percentage of clinker in concrete is critical to making the production of hollow core slabs more sustainable in the future and in general, to meet the ambitious CO2 reduction targets outlined in the European Green Deal of being climate-neutral by 2050. The possibility to reduce the CEM I dosage and/or to substitute it with clinker-reduced cement types or with supplementary cementitious materials (SCMs) offers significant improvements in reducing the embodied carbon of hollow core slabs. However, it leads to significant performance issues, especially low strengths development at both early and late ages.

As a leading supplier of concrete admixtures with more than 100 years of experience in the field, Master Builders Solutions aims to mitigate these drawbacks and help to fully exploit the potential of CO2 reduction associated with low-clinker concrete. The newly developed strength-enhancing admixture, Master X-Seed STE 35, enables concrete mix optimization promoting more sustainable construction. Master X-Seed STE 35 enhances cement hydration and improves the growth of the Calcium Silicate Hydrate crystals. Master X-Seed STE 35 markedly accelerates hydration at early (16-18 hours), medium, and long ages (14-28 days), providing the proper mechanical properties required to optimize clinker content.Two cases are described below where the use of Master X-Seed STE 35 successfully contributed to the reduction of clinker content without any negative impact on the fresh and hardened properties of hollow core slab mixes.

Case 1 – CEM I 52.5 R reduction

In this example, CEM I 52.5 R is used by the hollow core slab producer. The machine in scope is an extruder that works with the dry concrete mix at 0 cm slump (Figure 1). The considerably high amount of cement in the reference mix is because the test was carried out during wintertime (external temperature of 5°C) and there was no heating system available in the plant. Additionally, no superplasticizer admixture is used in the mix. In the low-clinker mix, 50 kg/m3 of cement was replaced by volume with an equivalent amount of sand, and Master X-Seed STE 35 was added at a dosage of 1% by cement weight to boost the strength development. The water content was adjusted to keep fix the water-to-cement ratio and to ensure the same extrusion capability (Table 1).

The total global warming potential (GWP tot) is estimated based on Ecoinvent 3.8 world datasets and industry average EPDs, considering the raw material supply (A1), transport (A2), and manufacturing (A3) for these calculations: 37 kg CO2 eq/m3 savings are possible with the low-clinker mix, equivalent to a 10% reduction in CO2 emissions.

Despite the lower amount of cement paste in the low-clinker mix, the element was extruded at the same speed (around 1,5 m/min) as the reference and with an equivalent finishing (Figure 2).

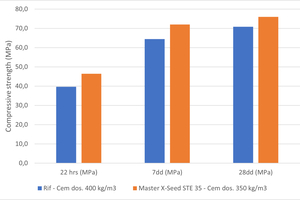

Because of Master X-Seed STE 35’s effect, the reduction of the cement content in the low-clinker mix does not affect the compressive strength measured on 15x15x15cm concrete cubes according to EN 12390-3 (Figure 3). The values of the low-clinker mix are even better than those of the reference mix, both at early ages and after 28 days.

Case 2 – Partial replacement of CEM I 52.5 R with CEM IV/A (V) 42.5 R

As shown in the previous example, reducing the cement content can bring savings in CO2 emissions in the range of 10%, directly proportional to the amount of cement diminished. To further reduce the CO2 footprint in the production of hollow core slabs, it is possible to partially replace CEM I 52.5 R with a clinker-reduced cement type.

In this second case, CEM I 52.5 R was partially substituted with a CEM IV/A (V) by the hollow core slab producer, keeping the same total amount of cement as in the reference mix. The machine in scope is again an extruder and the concrete consistency is slump 0 cm. Table 2 reports the mix design of the reference mix and of the low-clinker mix: in the latter, 55% of CEM I 52.5 R is substituted with CEM IV/A (V) 42.5 R. Additionally, the water content and the superplasticizer dosage are slightly adjusted to ensure the proper extrudability of concrete and Master X-Seed STE 35 are added at 1% on the total binder weight to boost strength development. The CO2 reduction with respect to the reference mix is about 20%. In this case, the GWP evaluation was conducted considering the specific EPDs of the two types of cement in scope.

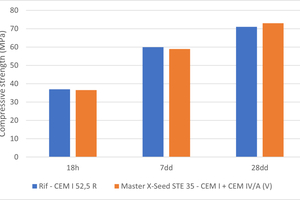

As in example 1, the element produced with low-clinker mix was extruded at the same speed (around 1,3 m/min) as the reference and with an equivalent finishing. However, the partial substitution of CEM I with CEM IV/A (V) could represent a huge challenge in terms of strength development. Thanks to the introduction of Master X-Seed STE 35 to the concrete recipe, the partial substitution of the CEM I with the CEM IV in the low-clinker mix does not affect the compressive strength measured on 15x15x15 cm concrete cubes according to EN 12390-3 (Figure 4): the values with the low-clinker mix are similar to those of the reference mix, both at early ages and after 28 days.

Conclusions

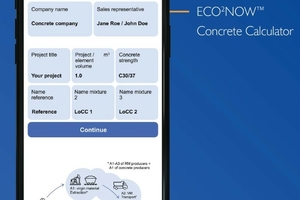

Master X-Seed STE 35 is an engineered strength-enhancing admixture developed in the R&D laboratories of Master Builders Solutions. With its unique mechanism of action, Master X-Seed STE 35 supports sustainable construction through concrete mix design optimization. The strength-enhancing property of Master X-Seed STE 35 admixture allows a reduction in the total clinker content of a given concrete mixture while maintaining compressive strength development equivalent to that of reference concrete, with associated benefits in CO2 emissions reduction. For this reason, Master X-Seed STE 35 is strongly recommended for the production of sustainable precast elements and manufactured concrete products (MCP), especially in the production of hollow core slabs. To further support customers in addressing the challenges of rising energy and the need for low-carbon concrete recipes in the construction industry, Master Builders Solutions has developed a new analysis tool called ECO²NOWTM (Figure 5). With the help of this tool, we can compare and optimize concrete recipes in terms of embodied carbon (CO2 emissions) and costs, filling a gap in the market with a comprehensive solution that offers ecological and economic comparisons of concrete recipes.