All in Precast – Bauma 2016

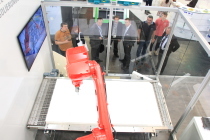

Under the theme ’All in Precast’, Vollert will be presenting new plant and machine concepts for stationary and fully automated production of precast concrete elements from April 11 to April 17 at the bauma 2016 in Munich (hall B1, booth 206). Taking centre stage is the award-winning and further improved ISO-MATIC 2.0, among others, which cuts insulating material to exact specifications fully automatically. A CAD-CAM-controlled 6-axis cutting robot equipped with a water jet cutting head contours the material using 4,000 bar water pressure and a high positional repeatability.

But modernization projects are also a major topic. Manufacturers of precast elements are focusing on upgrading and retrofitting existing plant technology to modern production standards in order to counter the growing competition for customers. Shuttering robots, automatic concrete spreaders and high-performance turning devices have revolutionized manufacturing processes and increased profits. For higher output capacities and a more precise positioning of the shutter systems, at Rector Lesage in Berre L’Etang the gripper system of the shuttering robot installed in 2006 has now been replaced and a magazining robot complemented. The new gripper operates at a much higher level of accuracy when plotting contours and positioning shuttering systems.

New residential housing for Thailand and India

Interesting new engineering projects are currently underway in Asia. In an effort to meet the rising demand for real estate in Thailand, the national construction industry continues to invest in modern plant technology for the production of precast concrete elements as is the case with the Siam Cement Group (SCG Group). In future, up to 2.2 million square metres of solid concrete elements will be manufactured annually in Saraburi Nongkae and Chonburi, located northeast and southeast of Bangkok, respectively.

India’s construction industry is also making greater use of precast elements in response to the sustained boom in the housing and building sector. Sobha is set to manufacture up to 400,000 square metres of large-area walls and slabs each year in its new precast concrete plant in Bangalore, thanks to a turn-key plant solution from Vollert. Complex, special-purpose concrete parts, precast stairs, façade elements and structural, reinforced concrete elements such as columns and beams are made using stationary formwork equipment from specialist Nuspl, which has also been part of the Vollert Group since 2012. Read more about it in this issue. With projects like these, Vollert represents the competent know-how partner for turnkey customer solutions at the bauma 2016.