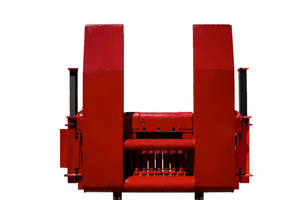

All new PipeMaster 3100 and 3206 Unloaders

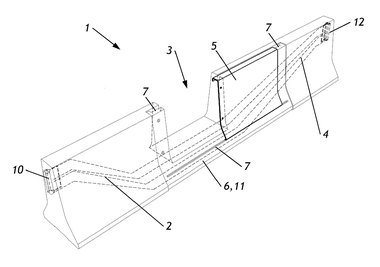

To improve the safety, performance, and maintenance of the PipeMaster Concrete Pipe Unloader, the new series 3100 has been developed. The series 3100 PipeMaster features these new design benefits as compared to the original series of unloaders.

New 50% wider forks

The new 50% wider forks give added safety when an improperly aligned pipe is rolled off the trailer.

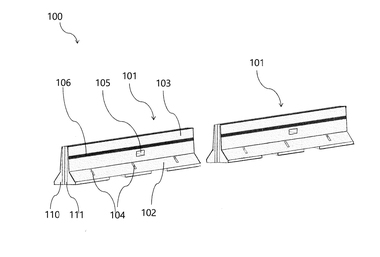

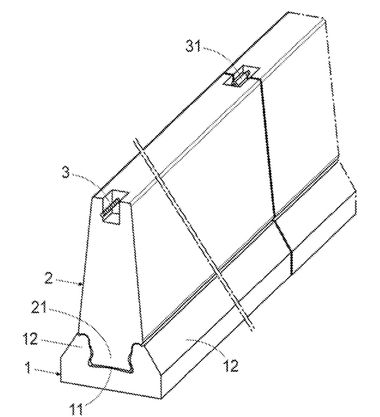

New eStop supplemental safety barrier

The new model 3100 PipeMaster is equipped with an eStop Supplemental Safety Barrier. This barrier is designed to stop an unchocked pipe from rolling off the end of the trailer when the PipeMaster’s unloading forks are in the down position. This barrier helps shield the operator from possible injury or death if he neglects to properly chock the pipe on the trailer.

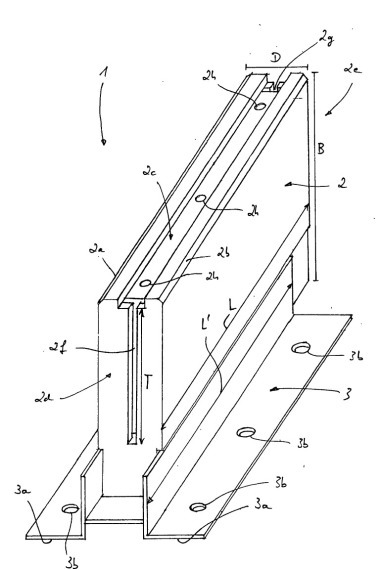

New manifold technology

The new manifold technology eliminates hydraulic joints. Eliminating joints helps alleviate leakage and air entrapment in the system. Dash pot hydraulic systems, as used with the PipeMaster, generate vacuum during operation. This vacuum tends to pull air into the system through worn piston rod seals and loose hydraulic joints. The 3100 Series incorporates a dome to collect entrapped air. A single, easy-to-reach pushbutton allows air to be expelled from the system.

New diode rear identification lamps are an integral part of the Model 3100. They are in a well-guarded location and can easily be connected to the trailer’s electrical system. Increasing the capacity of the oil supply permits longer maintenance interval.

The new Model 3206 PipeMaster

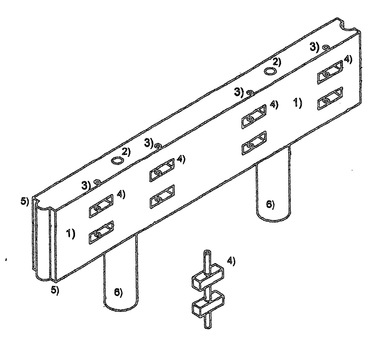

To improve safety, performance, and maintenance of the PipeMaster Concrete Pipe Unloader, the new series 3206 has been developed. The series 3206 PipeMaster features the following new design benefits as compared to the original series of unloaders.

The new model 3206 PipeMaster is equipped with an eStop Supplemental Safety Barrier. This barrier is designed to stop an unchocked pipe from rolling off the end of the trailer when the PipeMaster’s unloading forks are in the down position. This barrier helps shield the operator from possible injury or death if he neglects to properly chock the pipe on the trailer.

New manifold technology

The new manifold technology eliminates several hoses and hydraulic joints. Eliminating joints helps alleviate leakage and air entrapment in the system.

Dash pot hydraulic systems, as used with the PipeMaster, generate vacuum during operation. This vacuum tends to pull air into the system through worn piston rod seals and loose hydraulic joints. The 3206 Series incorporates a dome to collect entrapped air. A single, easy-to-reach pushbutton allows air to be expelled from the system. All bleeder petcocks are accessible with unloader on trailer. Access to the petcocks is readily available if system bleeding is required.

New rear identification lamps

New diode rear identification lamps are an integral part of the Model 3206. They are in a well-guarded location and can easily be connected to the trailer’s electrical system.

Increasing the capacity of the oil supply permits longer maintenance interval.

Visual sight gauge permits oil levels to be checked without removing the unloader’s inspection cover plate.