BAU 2017: Technological optimizations for precast concrete elements

The higher the degree of prefabrication at the factory, the lower the assembly and construction errors occurring under time pressure and adverse construction site conditions. Increasing the degree of prefabrication also means an increase in the certainty of costing and optimizes the construction proc-ess, as less individual services and materials for the construction process have to be organized and controlled.

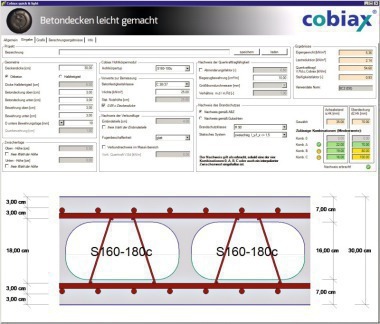

According to the manufacturer Cobiax, the product line „Slime-Line“ with its flattened void formers made from plastic is particularly suited to the use at precast concrete plants, for manufacturing semi-precast and precast elements.

The Cobiax technology applied in semi-precast elements and precast elements enables the precast concrete industry to expand the fields of application as well as marketing opportunities. By using the void formers made from plastic, the manufacturers of precast concrete elements, moreover, can follow the trend of offering more effective and efficient products which are more and more in demand, above all when it comes to building certifications according to DGNB, LEED or BREEAM.

By today, Cobiax can show about 10 million m² of voided flat slabs as reference implemented all over the world. A national technical approval was granted for the products „Eco-Line“ and „Slim-Line“ each.

Optimization by reduction

The Cobiax technology is based on generating closed hollows inside a reinforced-concrete area and/or floor slab. By using these closed synthetic void formers made of recycled material, concrete is replaced exactly there, where it is not required for structural reasons.

Under identical boundary conditions, such as concrete grade, deformation control, dead load, traffic load and span, a „Cobiax voided flat slab“ is up to 10 % thinner than a solid reinforced-concrete slab. Furthermore, the bending reinforcement required in terms of statics can be reduced by 15 %. The deadweight of the slab is reduced by up to 35 % simultaneously. In case of an identical deadweight, a Cobiax voided flat slab can be produced with a span increased by up to 40 % in comparison to a solid reinforced-concrete slab.

Cobiax can refer to a number of practical examples which effectively demonstrate how easy it is to produce semi-precast and even precast elements and how efficient and practical the further process is carried out on the construction site.

The Cobiax technology can be used for precast and semi-precast floor slabs, for staircase landings, for balcony slabs, precast concrete walls and shafts. The combination of Cobiax void former technology and the manufacturing know-how of the precast concrete plants offers far-reaching advantages, such as the possibility of subsequent opening of structural components, the integration of anything necessary for building services, as conduits, ductworks, embedded parts and block-cuts.

Cobiax void former modules

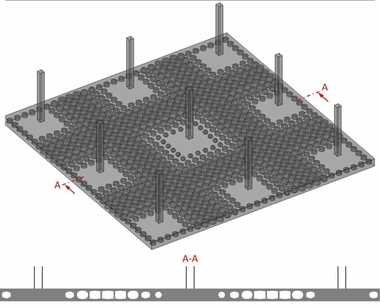

Using Cobiax void former modules in semi-precast floor slabs is another step towards factory production, independent of weather conditions and in favor of an accelerated construction process on the construction site.

The yoke spacing can be increased, lattice girder geometries can be optimized, less concrete must be ordered, supplied, placed and compacted and the spans of prefabricated floor slabs can be increased, among others, because of the reduced deadweight of the floor slab.

At first, the semi-precast elements are manufactured at the precast factory. Immediately thereafter, the void former modules in a row or even individual ones, depending on the specification of the installation plan, are put on the fresh concrete between the lattice girders and are slightly pressed into the fresh concrete of the thin semi-precast slab.

After adequate curing of the concrete, the semi-precast elements including embedded Cobiax void former modules are supplied to the construction site for installation. Afterwards butt joints and/or transverse reinforcement are installed.

The installation of the upper reinforcement layer and the subsequent concreting process do not differ from the conventional procedure. It is not necessary to take additional measures to secure the void former modules against buoyancy during concrete placement.

Cobiax void former modules in precast concrete elements

In the constant effort to build more efficiently, more intelligently and in a material saving way, the application of Cobiax void former modules has established itself in precast construction, in addition to using the Cobiax technology in cast-in-situ slabs, as a particularly efficient and technically optimum solution. They are used, for example, in the field of precast concrete floor slabs for single-family or two-family houses, for office and industrial projects as well as for hotels and functional buildings such as transformer stations and also garages. Balcony and landing slabs have proven to be very suitable, too.

The reduced weight of the precast concrete elements which is due to the void formers made from recycled plastic material result in advantages in terms of statics and logistics and facilitate handling during installation. Not least due to the fact that the crane capacity required can be reduced considerably, among others. Balcony slabs as precast concrete elements combined with void former modules provide for an additional crucial advantage, as the lower deadweight of the component allows for smaller dimensions of the thermally insulated component and thus saving costs.

In contrast to other precast concrete slabs, such as hollow core slabs, precast concrete slabs manufactured with Cobiax technology enable load transfer in two directions and any slab width – with and without prestressing – and can be manufactured at almost any precast concrete factory.