Balcony connections for maximum thermal insulation

In the construction of balconies, the applied forces must be brought into static equilibrium. In addition, the requirements placed on thermally insulated and airtight façades are strict. H-Bau Technik GmbH has offered appropriate solutions for meeting these challenges for many years. With its Isomaxx elements and their notably improved insulation values, the company offers a further development of its Isopro elements.

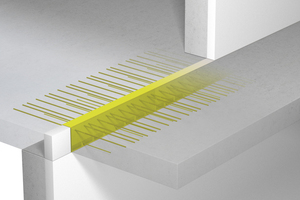

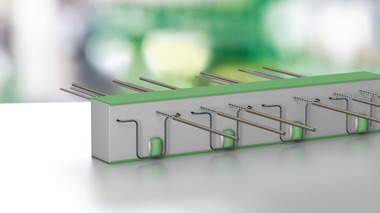

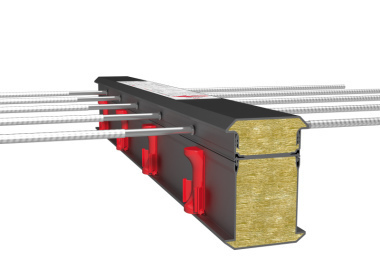

The elements reliably establish load-transmitting mechanical connections between the external and interior structural concrete components. They establish structurally sound connections between concrete constructions and the main supporting structure of the building, while preventing at the same time thermal bridges. The embedded tension and shear-force bars, as well the thrust bearings, reliably transmit moments and shear forces. These properties reduce heat loss without loss of the structural loadbearing capability.

Use of high-strength stainless steel

The construction supplier H-Bau Technik from Klettgau, in the German region of southern Baden, succeeded in reducing at the insulation joints the cross-section of reinforcement by about 36 % in the tension areas for both Isomaxx and Isopro. This reduction was achieved by using high-strength stainless steel.

The thermal insulation elements from H-Bau Technik reduce thermal bridges, offering customers in this way numerous advantages. The use of Isopro and Isomaxx prevents structural damage, which significantly reduces energy and thus offers a sustainable solution for the construction sector. The high thermal conductivity of concrete and the large surface areas of the connected external structural elements – as compared to the cross-section of the connections – lead to significant heat flow in the presence of uninsulated or insufficiently insulated connections. This of course results in the formation of condensation on cold surfaces in the interior – which, again, results in mold growth. The use of Isopro and Isomaxx elements from H-Bau reliably eliminates these weak points. The stipulations in EnEV and DIN 4108-2 p. 2 are more than complied with.

Installation advantages result in weight reduction

The increase in thrust-bearing forces enables Isomaxx elements, fitted with concrete thrust bearings, to achieve significantly higher supporting levels, up to IM 100 – which offers numerous advantages. In some elements, this eliminates the need for steel thrust bearings, which are replaced by a more compact alternative consisting of special concrete. That means, apart from weight reduction, that the bearings, which now terminate at thermal insulation bodies, have considerable installation advantages over the earlier manner of execution. In addition, heat flow in the structure is reduced to a minimum.

The DIBt has already supplemented its approval regulations Z-15.7-243 and Z-15.7-244 to account for the further developed Isomaxx elements. These are generally available in heights of 160 mm to 250 mm. The thrust bearings consist of high-performance special concrete and the insulation elements of Neopor hard-foam polystyrene.