Bolted connections for a huge warehouse in Spain

Booming online business requires investments in the logistics infrastructure. Amazon meets the growing demand with a 100,000 m2 warehouse.

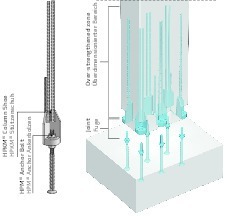

A soon-to-be logistics hub to serve in the Madrid area, the Amazon warehouse rises three-storey high above the ground floor. The entire frame was designed with precast columns, beams and hollow-core slabs. Thanks to previous successes, the precaster Tecnyconta-Consolis chose Peikko. “With more than 400 columns with a length of 22 meters each, using bolted connections was a logical choice. Peikko’s solution increases work safety and reduces the risk of accidents,” says Óscar López de Sola, Technical Office Manager of Tecnyconta-Consolis.

Having such a quantity of columns to erect, speed and safety are crucial for making good progress on site. A bolted connection can be installed in any weather conditions. And when the bolts have been precisely installed to the foundation, it’s easy to keep the rest of the structure within tolerances.

No propping, increased safety, and less crane time

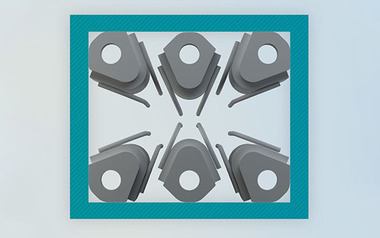

“By using conventional column connection methods, propping would have been needed to allow the grout to cure – a work phase that not only makes the construction slower, but also is a safety hazard with the unnecessary obstructions created by the propping and the risk of failing bracing was totally avoided with the column shoes,” says Adrián ListeSales Director of Peikko Spain.

The ability to easily level the column with nuts helped to keep the pace of installation high. “As soon as the nuts are tightened, the connection is moment bearing, and the erection crew can move on to the next column. This translates into lower crane time and cost savings. The whole frame is built in a lego-like manner – erect the columns, install the beams, and hoist the hollow-cores in place,” Liste explains.

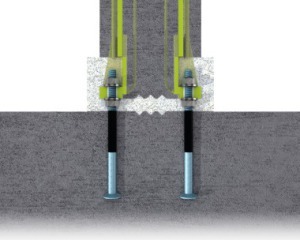

Making holes to the hollow-core

There are more than 100 openings in the hollow-core, so the ability to easily create them with Petra Slab Hangers did benefit both the design and construction phases.

“The structural designer was able to skip the time-consuming static analyses and tailor-made structural solutions. In the construction phase, the installation of slab hangers and hollow-core was straightforward,” says Liste.

Efficient deliveries

More than 2,000 column shoes were delivered from Peikko to the precasters’, on time. The anchor bolts from size M20 to M45, and around 200 customized Petra Slab Hangers were delivered directly to the site.

“We always aim to do the deliveries as efficiently as possible. In this case, four full truck loads were needed to transport the hardware.” The project will be completed by the end of 2021.

CONTACT

Peikko Group Corporation

P.O. Box 104

Voimakatu 3

15101 Lahti/Finland

+358 20 707 511