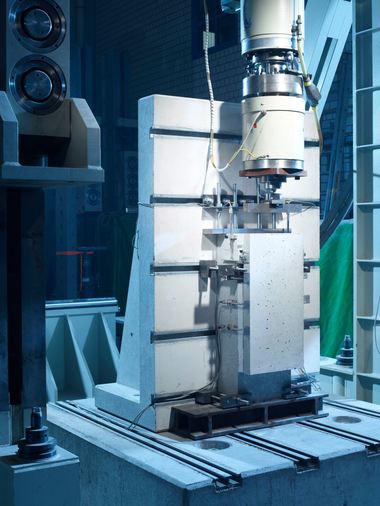

C-up – Upcycling of carbon fiber scrap for UHPC applications

Ultra-high-performance concrete (UHPC) is used for slender structural

members with high load-bearing capacity. The wide range of UHPC applications includes structural frameworks, façades, prestressed bridge elements, wall panels and industrial floors, and a large number of projects have already been completed worldwide.

In each case, UHPC solutions proved to be the most favorable when two or more of their specific advantages came into play compared

to conventional solid concrete structures. If the performance aspects can be combined, more efficient building systems can be realized with less material and energy input.

In the future, criteria will be extended to include sustainability and carbon footprint. This opens up new perspectives for UHPC in concrete construction. Sustainability is achieved by extending the service life while the carbon footprint is reduced by achieving material savings.

In the C-up project, the principle of reinforcing UHPC with short steel or carbon fibers is being developed further. In a special

refinement process (carbon-stick process), carbon fiber residues from production and end-of-life components are converted into a new product. The resulting carbon stick is then to be added to the UHPC as a reinforcing element. In addition to a massive cost reduction, the aim is to extend the life cycle of high-quality reinforcing fibers by several decades. At the same time, the carbon footprint is reduced by saving concrete mass. The concrete components’ corrosion

behavior, surface quality and life cycle can thus be improved.