Chinese construction group banks on UniCAM.10 master computer

Commissioned by one of China’s largest construction groups, Unitechnik is fitting two precast concrete plants with the latest model of its master computer. The software controls the entire production process, thus being a contributor to maximizing productivity of the production locations. With the new installations, four plants in total are currently operated in China using control technology from Unitechnik. To ensure that this number continues to increase, Unitechnik presented its master computer at the BetonTage asia and the Engineering Days in Beijing in November 2016.

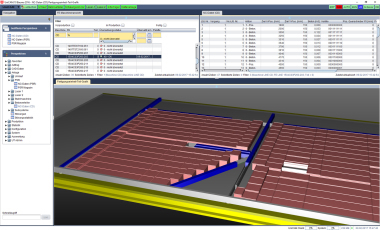

To ensure a continuous exchange of information in the two newly built precast concrete plants, UniCAM.10 is connected to both the CAD system and the production machinery via the open Unitechnik interface. In addition, the automation expert based in Wiehl is supplying the required control technology for the pallet circulation system, automated concrete distributor and shuttering robot. A laser projector and the reinforcement plant operating with external control systems are connected to the master computer via a sub-system interface.

Efficient production control is realized by the master computer based on the data transmitted. The automatic pallet assignment feature, for example, optimizes space utilization on the production pallets. Another benefit is the self-learning cycle time homogenization feature which ensures a steady flow of the pallets through the plant. In addition to production control, UniCAM.10 features an integrated production data and station time logging feature which offers comprehensive reporting options. The user can always see, at a single glance, the number of concrete elements produced in a specific time interval, the amount of steel used, and the processing time per station. Control and visualization of the production processes are possible at the computer and via all mobile devices.