Laser projectors replace plotters in Austrian precast plant

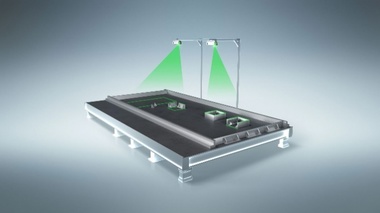

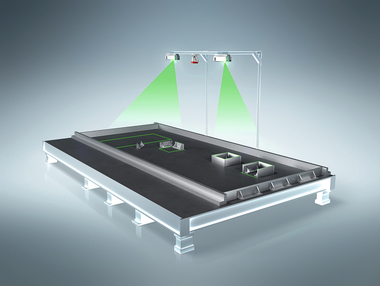

At its Gerasdorf location near Vienna in Austria, Mischek Systembau GmbH is now using laser projectors from Unitechnik for the production of solid walls. With its investment, this manufacturer of precast elements replaces its previously used plotters. The twelve new UniLaser units are used for labeling pallets to enable accurate placement of formwork, embedded parts, and blockouts. The projection systems communicate with the mastercomputer, UniCAM, and are in this way optimally integrated into the production process.

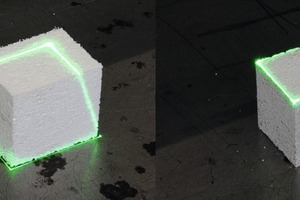

As a subsidiary of Strabag AG, Mischek manufactures reinforced-concrete elements such as solid walls, floor plates for floor systems, and other structural precast components on a production floor of more than 30,000 m². The precast elements are transported on pallets on a platform car from one workstation to the next. Until now, the contours of the concrete elements as well as the positions of the embedded parts and the blockouts were plotted onto the pallets. Mischek has now replaced this system with modern laser projectors to free up additional production space in the plant. The systems from Unitechnik lower operating and maintenance costs and enable buildup of three-dimensional contours. And because laser projection does not use color markings on the pallets, the surfaces of the pallets are not discolored.

Integration into

the production system

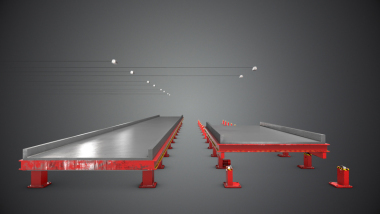

Six work stations in total were fitted with UniLasers: two shuttering stations and four work stations for reinforcement and embedded parts. Due to the pallet lengths of 7.20 m and the low erection height of 3.65 m, dictated by plant conditions, two projectors with 5 mW ratings are used at every station. The projection zones of the two lasers overlap by 30 cm, which enables the system to accurately position the parts on the production pallet. The laser projectors are integrated in the UniCAM master computer, also from Unitechnik, with which the projection images can be created. For this purpose, the operators determine for every image the required contours, blockouts, or embedded parts and define the height to which the individual elements are to be projected. In addition, text information can be projected onto the pallets. In this way, up to 16 images can be configured and projected per laser station. These images can be superimposed by remote control from the workstations. At the control panel, UniCAM displays all projections from the six laser stations side by side.

The calibration function is a special feature of this Unitechnik solution since the workstations at Mischek are not fitted with a centering unit for pallets. For this reason, calibration takes place by projecting a setup contour, which consists of the two pallet edges at the sides, the fixed edge formwork, and a parallel offset guideline. The setup contour is adjusted by remote control to the exact position of the pallet.