Combinable module for impact wear protection

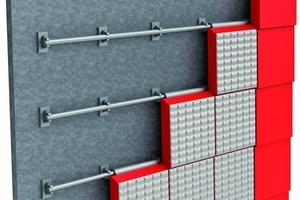

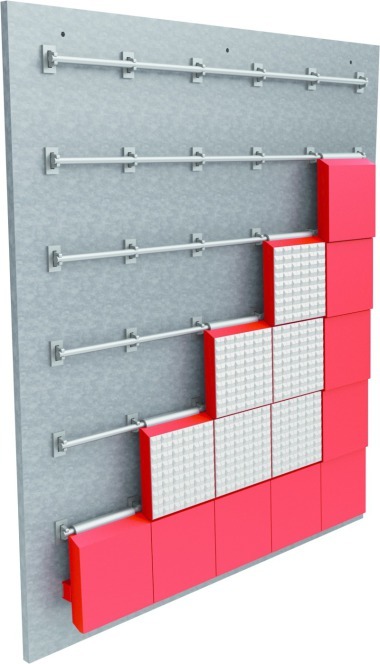

Impact plates of new modular design cater to increasingly cost-consciousness companies without cutbacks in the quality of reliable wear protection. In this way, lower maintenance and repair costs can be combined to obtain very good wear protection results. A new development ensures optimization of impact wear protection: the innovative fan-type impact wall from Pucest is a system of modular plates made of different materials that can be freely combined.

By combining the Pucest PU modular plate with high wear resistant hard metal and/or steel plates for maximum impact wear protection, different impact loads can be reacted to. A buffer and clamping ledge provides additional safety and stability. The sound-insulating properties of Pucest PU considerably reduce noise emission.

Modular plates made of different materials

The wear rates of impact plates vary. Worn modular plates of the fan-type Pucest impact wall can be easily and quickly removed and replaced with modular plates of hard metal or steel. The easy removal of the worn plates and the short time required for replacing it in the holding ledges, reduce repair and maintenance costs to a minimum. The previous disadvantages of conventionally fitted impact plates, e.g. complex assembly and the in most cases required complete exchange of frequently only partly worn elements are thus a thing of the past.

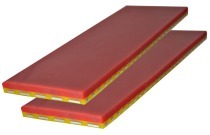

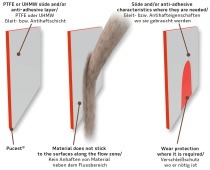

Another of Pucest Protect GmbH’s recently presented developments is the reparable signal wear protection plate that due to its outstanding resistance to wear and abrasion not only offers a long service life, but also signals the need for replacement in good time. This is of particular importance in places where inspection of the lining thickness is difficult.