Concept, notes, and recommendations for design and technical execution

In the past, concrete constructions impermeable to water were primarily designed with restricted crack width, with the objective of enabling self-healing of the designed separating cracks. However, this objective cannot always be reliably met for high-quality utilization of basement floors, WP roofs, and structural members subjected to chloride attack – since in such cases the planned serviceability properties are not dependably achieved. The WP Code of Practice [1] takes this aspect into consideration in calling attention to additional possible design principles, and by providing a description of the required measures for such cases. This calls for rethinking the structural design, extending from pure dimensioning work and proceeding to design engineering, and for making allowance for restrained deformation.

The new WP Code of Practice [1] contains supplementary regulations for ensuring serviceability, making allowance for special requirements encountered generally for water impermeability in building construction and commercial buildings. This new code also deals with construction of basement floors embedded partly or completely in the ground, as well as for concrete roofs without additional sealing.

Significant changes in the new WU code of practice are:

Description of the required design steps as guideline for overall planning

Clarification and detail definition of the design principles and required measures for implementation

Detail definition of requirements for communication, documentation, and verification requirements

Inclusion of regulations for WP roofs

Provision of stricter requirements for Design Principle b), with self-healing of cracks

Increasing the requirements for WP wall elements with minimum element thickness

Inclusion of an informative annex with orientation aid for coordinating the responsibilities assigned for the design and implementation of WP concrete structures (i.e., checklist)

Description of the documentation requirements

In contrast to the experience gained in the implementation of WP construction in the past for high-quality utilization, coordinated planning with all parties involved – whose responsibilities must be clearly delineated before the start of project – is necessary to satisfactorily achieve the objectives of building use. These parties include project planners, structural engineers, building services planners, building physicists, soil surveyors, and concrete technologists. For this purpose, all parties will ideally be provided with a checklist in the annex to the WP Code of Practice for specifying their responsibilities. The objectives of utilization must be clearly defined by the client and the project planner at the beginning of the project, within the scope of a requirements analysis.

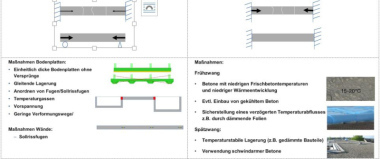

Alternatively to Design Principle b), the two principles a) “Crack prevention” and c) “Allowing cracks, with subsequent durable sealing” are already described as technically equivalent in the first WP Code of Practice [2] and the measures then required for reducing restraint [3] are stipulated. Additional explanations for implementing Design Principles a) und c) are contained in the new WP Code of Practice.

With Design Principle a), measures involving structural engineering, concrete technology, and technical execution are described for designed prevention of separation joints by reducing the restraint stresses to such an extent that they do not at any time exceed the respective tensile concrete strength.

Design Principle c) is aimed at specifically forcing individual cracking at specific points or to allow for a minimum number of individual cracks with larger crack width. These planned cracks are later durably sealed: for example, by sealing injections or by individual crack bandages (for underground garages). The calculated crack width is stipulated under aspects of durability at 0.3 mm on the side exposed to water and at 0.4 to 0.5 mm on the inner side. Durability is ensured by long-term sealing of the cracks.

Design Principle b) can no longer be used for high-quality utilized WP constructions and WP roofs, because Service Class A cannot be achieved in this way. If the design principle is to be applied for other uses, the hydrostatic pressure must – for determining the design value of the separating crack widths for planned self-healing – be considered in addition to the pressure gradient, with the hydrostatic pressure being restricted to 10 m (Table 2 in [1]).

The minimum member thickness in Table 1 of the WP Code of Practice was supplemented by providing values for WP roofs. These values are lower than comparable wall elements, because manufacturing conditions for producing floors are more favorable.

To ensure reliable execution of precast walls, the requirements applied to the clear distances between the interior connecting reinforcement and/or between the interior surfaces of the precast panels and simultaneous installation of inner joint sealing have been supplemented such that the minimum member thickness may still be utilized only if this clear distance is maintained. Furthermore, the required depth of roughness of 0.9 mm can be increased to 1.5 mm.