Custom precast specialist Klaus relies on fully customized automation solutions

Klaus Hoch- und Tiefbau GmbH added several new automatic machines supplied by Progress Maschinen & Automation and Tecnocom – two members of the Progress Group – to its precast plant equipment range. These rebar processing machines and mold systems were tailored to the needs of the company based in Kissing near Augsburg, Bavaria, which is now able to produce its wide range of custom stair elements even more easily and with a higher degree of automation.

Klaus Fertigteilwerk focuses on the manufacture of custom precast elements and anything beyond the usual standards, including, for example, spiral stairs. The precast business is a subsidiary of Klaus Hoch- und Tiefbau GmbH, and thus a member of the Klaus Group. The Kissing precast plant has been in operation since the late 1960s. Under the Klaus brand, it has evolved continuously to become a state-of-the-art business currently employing about 115 people. Located south of the city of Augsburg, the precast plant covers the Bavarian and Baden-Württemberg markets, supplying top-class, customized precast components such as stairs, balconies, façade panels and bespoke elements. The company almost exclusively serves the residential construction or private home segment; it has only a very minor share in the industrial construction market.

Machines tailored to the needs of the custom precast specialist

The newly installed multi-purpose Pluristar machine supplied by Progress Maschinen & Automation merges the features of an automatic stirrup bender, straightener and double-bending machine in a single system. It can process wire diameters from 8 to 16 mm and is equipped with a combined straightening system consisting of a roller and a rotor straightening unit. This unique combination allows for the flexible manufacture of stirrups, straight rebar and rebar with large bends, thus covering the entire work step of processing rebar from the coil.

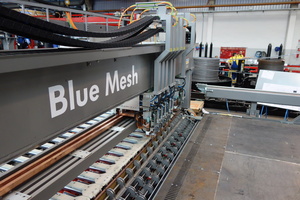

The rebar processing station also includes a new M-System BlueMesh mesh welding system, which provides a high degree of flexibility. This custom machine welds mesh from the coil according to individual specifications. It is easy to operate and produces mesh exactly in the required dimensions, thus preventing offcuts because it processes the rebar directly from the coil. It excels with its low energy consumption and compact footprint as well as low-cost operation. In addition to welding, the machine allows for the custom bending of reinforcing steel mesh, which ensures a high-quality finished product so that Klaus is able to manufacture its custom precast elements effortlessly and in an automated process. On average, the system produces close to 50 reinforcement cages per day, but it also allows for a greater output of up to 75 cages per day in different sizes in the case of high demand.

Thomas Heubeck, Technical Manager at Klaus Fertigteilwerk, comments on the investments made: “The new machines enabled us to take a big leap in our reinforcing steel fabrication since we are now able to produce custom cages for our stair molds. All we have to do is to fix the base cage to the bracket stirrups.” He adds, “For straight stairs with or without landing, the reinforcement is manufactured to size so that ironworkers only need to perform control measurements.”

The process of manufacturing spiral stairs is a bit more complex. For this purpose, the mesh welding system cuts rebar to the meter for the top and bottom reinforcement layers as well as for the perimeter cages. This rebar can be cut to the required size and inserted for the spiral stair.

Klaus additionally invested in tailored staircase mold systems supplied by Tecnocom in order to enhance the high-quality production standard and degree of automation even further. These systems make it possible to perform shuttering works with pinpoint precision and in a fast, flexible and automated process.

“When sourcing the new mold systems, we chose Tecnocom because their products could be adjusted and manufactured to meet our specific needs. No other supplier was able to offer this,” Heubeck adds.

Tecnocom delivered an HT-TEC Plus staircase mold system, which is a specially designed tiltable staircase mold with 10 steps, a Ramp-TEC Plus staircase mold system and a stationary table.

The Ramp-TEC Plus system is an automatically adjustable ramp mold for stairs with landing and makes it possible to vary the inclination of both the ramp and the landing automatically. Its integrated inclination sensors allow for variations in the rise of the step and automatic adjustment of the inclination of the landing via electric controls so that the molds can be adjusted to the specific production requirements. In addition, the system provides the option of adjusting the length of the stair or the landing and ensures an impeccable surface quality. The stationary table has a polished casting surface in order to produce precast elements with a superior surface quality. It is possible to use lateral shutters for the manufacture of elements in different sizes and thicknesses. High-frequency or pneumatic vibrators compact the freshly poured concrete. The table is equipped with several heating systems to speed up the concrete curing process.

Progress Group – a reliable partner

According to Klaus, it was very important to choose a German-speaking supplier with a highly reliable customer support. Progress Group meets these requirements – there is no language barrier standing in the way of resolving even small issues quickly and easily.

Heubeck comments on this aspect: “Today I had a relatively long telephone conversation with support. If anything is unclear and problems need to be solved quickly, effective and efficient communication is essential.”

The investment decision was also supported by the positive experience other companies have gained in their collaboration with Progress. Any machine available on the market will be capable of bending, welding or shuttering, but Progress Group convinced Klaus Fertigteilwerk by offering an attractive all-in-one solution.