Cutting production costs through energy saving management

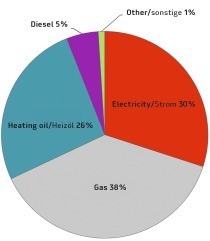

Rising energy costs, growing shortage of raw materials and an increased competitive pressure from global competition, but also a growing ecological sensitivity among the customers and consumers are just some of the reasons why companies opt for establishing an energy management system.

Energy costs have a considerable impact on production costs. Therefore, a reduction in energy costs directly results in a reduction of the production costs. The main objective is to save energy costs, because electricity tariffs for industry and domestic homes have gone up by 4.5 % on average throughout EU countries between 2008 and 2012. According to a survey carried out by Fraunhofer Institute, the potential for savings in German companies amounts up to 30 % of the energy consumption as well as the related energy costs and CO2 emissions. Savings of about 10 % are often even directly possible...