Development of an innovative modular bridge

In Germany, modular bridge construction methods have so far been applied only to a limited extent compared to other European countries or North America. However, public road authorities are increasingly promoting the continuous improvement of such techniques. Initial pilot projects have either been completed already or are currently under construction. The Hammacherstrasse composite steel structure at A46-motorway close to Hagen illustrates the enormous potential of modular bridges in terms of reducing the loss that the economy is sustaining due to traffic disruptions. Optimizing such bridges will increasingly move into the focus of research and industry.

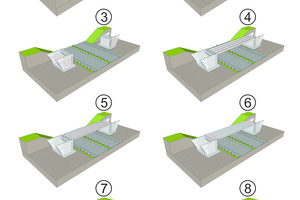

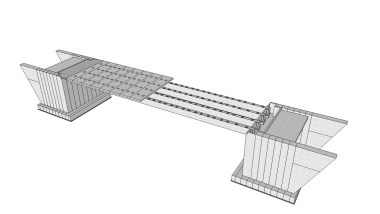

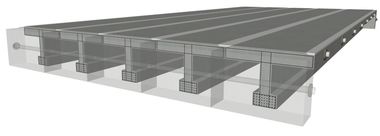

This is why the Institute of Structural Concrete at RWTH Aachen University closely collaborated with Nesseler Bau GmbH to conduct theoretical studies and experimental tests with the aim of developing an innovative design of a modular system composed of precast elements (Fig.). It permits the construction of bridges having a 50 m-span by using precast elements while significantly reducing the consumption of cast-in-place concrete and grouting mortar. As a result, the time to completion can be shortened from 12 to 15 months required for the conventional cast-in-situ technique to under 100 days.

Development of the design also included comprehensive experimental studies involving small- and large-scale tests in order to determine the individual detailing points of the newly conceived structures and to evaluate possible production methods. In addition, a structural design exercise was carried out for the entire structure and a traffic routing and diversion scheme was developed for the construction phase. This optimized modular bridge called n.Segmentbrücke (segmental bridge) thus meets all technical specifications and has already been tested in practice. In the next phase, the major benefits of the new design should be confirmed by a pilot project.