Investigations on modular bridge constructions made of CFRP reinforced concrete

In recent decades, the requirements for existing bridge structures increased significantly due to the strong growth of traffic volume and in particular due to the higher total vehicle weights. As a result, a large number of the existing bridges in Germany will have to be rehabilitated or reconstructed over the next few years. Both strengthening of existing bridges as well as necessary reconstructions are extensive, expensive and strongly influence traffic. Hence, the development of new methods for sustainable bridge constructions becomes a macroeconomic issue.

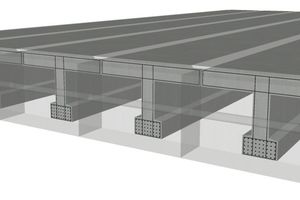

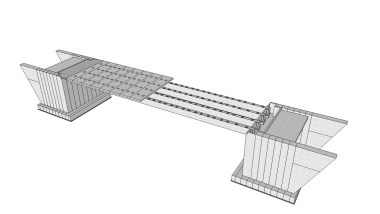

Modular bridge constructions made of prestressed precast elements

with reinforcement made of carbon fibre reinforced polymer (CFRP) are a promising approach to solve this problem. They enable

efficient and high-quality solutions for slender structures with

reduced construction periods and improved durability.

Therefore, investigations were conducted at the Institute of Structural

Concrete of RWTH Aachen University to develop a concept for a novel modular bridge system made of precast CFRP reinforced concrete

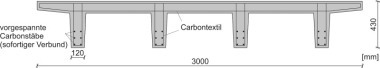

elements (Fig). As part of the process, the behaviour of the CFRP reinforcement in high-performance concrete (HPC) needs to be determined to achieve an economical and reliable design. To ensure reliable transfer of the prestressing force, investigations on the bond behaviour

of the pretensioned CFRP tendons were conducted. In addition, bending

and shear tests were performed to investigate the structural performance

of the precast elements with mixed untensioned and prestressed

CFRP reinforcement. Since the connection of the individual

modular precast elements by means of friction-locked joints is

another important issue, the structural behaviour of different joint designs was also investigated.