“Dortmund U” – huge school building project using prestressed concrete floor slabs

On the former plot of the Dortmund Union brewery the large-scale urban development project of the vocational college the so-called “Dortmunder U – Das Viertel” (“Dortmund U – The Quarter”) has been completed. The project was started in 2013. The Robert-Bosch-Berufskolleg and the new Robert-Schuman-Berufskolleg, an interdisciplinary sector, an underground parking lot as well as a new office building covering a rentable area of approx. 4,000 m² were built next to the famous U tower, the center of art and creativity, on a partial area covering 20,000 m² that belonged to former grounds of the Dortmund Union brewery. The investor group comprising Hochtief PPP Solutions GmbH, Hochtief Projektentwicklung GmbH and Kölbl Kruse was responsible for the realization of the project.

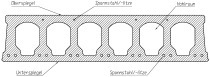

Zechbau GmbH as general contractor was responsible for the technical implementation of the overall about 52,305 m² of gross floor space and awarded a contract to Elbe Delcon GmbH (Elbe Decken) for production and delivery of about 17,000 m² of office floor elements with a thickness 25 cm. The architectural office Gerber Architekten was responsible for the design and construction planning.

Different ceiling heights

In terms of architecture, the modernization of the plot is characterized by open relationships regarding views and ways. “The spacious floor spaces provide room for quite individual solutions. Whether class rooms of different sizes, ample recreation rooms, cubicle offices or open space – everything is possible”, explains Martin Riechel, the project manager of Gerber Architekten. “Alternating ceiling heights are moreover used to visualize single areas and separate them from each other according to function. Flexible, but load-bearing: In this respect, the architectural concept imposed requirements which we were able to meet with prestressed precast concrete floor slabs in a particularly effective way.”

Right from the beginning, Zechbau GmbH had planned to use prestressed concrete floor slabs, and Elbe had been continuously supplying the construction site with floor elements in the summer of 2014. The construction schedule provided for adequate time frames for delivery and assembly of the floor slabs. “We have considered the supplies in the site logistics at an early stage. Hence, the installation of the prestessed precast concrete floor slabs could be integrated in the process without any problems,” reported Henning Timmer, project manager of Zechbau. “The just-in-time delivery worked very well, and the use of prestressed concrete floors shortened the construction process on site by several weeks,” stated Florian Lob, general site manager of Zechbau. Furthermore, the need of formwork and the storage area required for the floor elements was minimized, which enabled us to save additional costs. “The flexible delivery of the floor elements, being on schedule simultaneously, was the precondition for an optimized construction process and contributed to complete the building project ahead of time,” Timmer concluded.